Overview - Dental Implants Manufacturing

The demand for dental implants in Saudi Arabia is growing rapidly, but strict regulations ensure only high-quality products reach the market. Understanding the manufacturing process and regulatory landscape is crucial for businesses aiming to succeed in this field.

Why Dental Implants Matter?

Losing teeth affects millions of people globally, impacting confidence and oral health. Dental implants offer a permanent solution with improved functionality and aesthetics. However, ensuring safety and durability is key, which is why strict regulations exist in Saudi Arabia.

Looking For a Medical Device Regulatory Consultant?

Let’s have word about your next project

Common Challenges in the Industry

- High cost of non-compliant implants

- Increasing demand for biocompatible materials

- Struggles with regulatory approvals

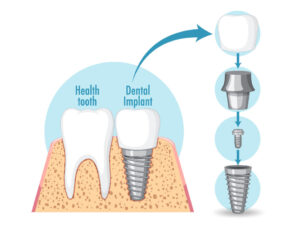

Manufacturing Process Overview

The manufacturing of dental implants involves several steps to ensure the final product’s quality, durability, and biocompatibility. Here’s a breakdown of the key stages:

1️⃣ Material Selection

- Titanium: Most commonly used due to its strength, corrosion resistance, and biocompatibility.

- Zirconia: A metal-free alternative, preferred for its aesthetic appeal and hypoallergenic properties.

2️⃣ Precision Engineering & Machining

- CNC Machining: High-precision cutting and shaping of implants.

- 3D Printing: Advanced manufacturing for custom-designed implants.

- Surface Treatment: Processes like sandblasting and acid etching to improve osseointegration (bone attachment).

3️⃣ Cleaning & Sterilization

- Ultrasonic Cleaning: Removes microscopic debris.

- Sterilization: Uses gamma radiation or ethylene oxide gas to ensure implants are free of contaminants.

4️⃣ Quality Control & Testing

- Mechanical Strength Testing: Ensures durability under chewing forces.

- Biocompatibility Testing: Confirms no adverse reactions with human tissue.

- Dimensional Accuracy: Verified using advanced measuring equipment.

5️⃣ Packaging & Labeling

- Sealed Sterile Packaging: Protects against contamination.

- Regulatory Compliance Labels: Includes product information, batch number, and expiration date.

6️⃣ Regulatory Approval & Distribution

- Compliance with ISO 13485, SFDA (Saudi Food and Drug Authority), and other global standards.

- Once approved, implants are distributed to dental professionals for patient use.

Regulatory Framework in Saudi Arabia

SFDA Regulations You Need to Know:

🔹 SFDA Licensing – Mandatory for manufacturers & importers

🔹 Medical Device Marketing Authorization (MDMA) – Approval for market entry

🔹 Compliance with ISO 13485 & GMP – International quality standards

🔹 Clinical Evaluation & Post-Market Surveillance – Ongoing safety checks

Ready to Streamline Your Dental Implant Manufacturing & Regulatory Compliance?

How Operon Strategist Can Help

As a leading medical device manufacturing and regulatory consultant, Operon Strategist simplifies compliance and optimizes production processes.

Our Expertise Includes:

- Regulatory Consulting – SFDA approvals & documentation

- QMS Implementation – Ensuring ISO 13485 & GMP compliance

- Process Optimization – Streamlining manufacturing efficiency

- Turnkey Project Consultant – End-to-end support for setting up compliant manufacturing units

- Training & Audits – Keeping your business compliant