Revolutionizing Healthcare with 3D Printing

Did you know that 3D printing is transforming the medical device industry by enabling customized implants, prosthetics, and surgical tools? With its ability to create complex, patient-specific designs at a lower cost, 3D printing is paving the way for groundbreaking advancements in healthcare.

What is 3D Printing in Medical Device Manufacturing?

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects layer by layer from digital designs. In medical device manufacturing, it is used to produce highly customized and complex products such as:

- Prosthetics

- Implants

- Surgical instruments

- Dental restorations

- Anatomical models

By leveraging 3D printing, manufacturers can create precise medical devices tailored to individual patient needs, improving both effectiveness and patient outcomes.

Need Assistance for 3D Printing Medical Device Manufacturing

Elevate your 3D printing medical device project with Operon Strategist. Contact us for regulatory compliance support, expert guidance on manufacturing plant layout design, and turnkey solutions for optimized medical device manufacturing.

Applications of 3D Printing in Healthcare

1️ Personalized Prosthetics & Implants

- Customized 3D-printed prosthetics ensure a perfect fit for patients.

- 3D-printed implants provide better compatibility with the human body.

2️⃣ Advanced Surgical Instruments

- Surgeons can use 3D-printed tools designed specifically for complex procedures.

- Disposable instruments can be printed for cost-effective single-use applications.

3️⃣ Dental & Orthodontic Solutions

- 3D printing enables precise dental crowns, bridges, and aligners.

- It allows for the rapid production of customized dental implants.

4️⃣ Bio-Printing & Tissue Engineering

- Researchers are developing 3D-printed human tissues for regenerative medicine.

- Future advancements may include printed organs for transplantation.

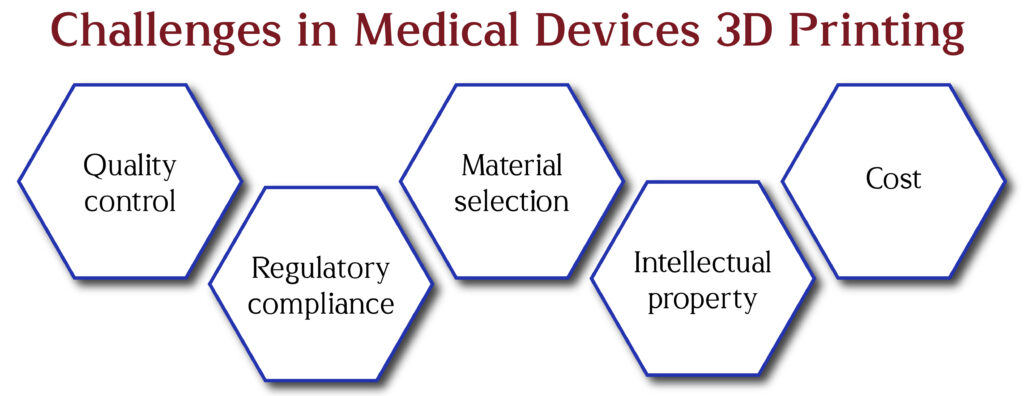

Challenges in Medical Devices 3D Printing

While 3D printing offers numerous benefits, it also comes with challenges that must be

- Quality Control: Ensuring precision and consistency in medical devices.

- Regulatory Compliance: Navigating evolving global regulations.

- Material Selection: Choosing biocompatible, durable materials.

- Intellectual Property Risks: Protecting proprietary designs.

- High Initial Costs: Investment in technology and training

📈 Potential Growth of 3D Printing in the Medical Industry

With increasing demand for personalized medical devices, 3D printing is expected to see exponential growth. Key advantages driving its adoption include:

✅ Faster Production: Reduced time-to-market for new devices.

✅ Lower Costs: Efficient use of materials and reduced waste.

✅ Innovative Designs: Creation of complex structures not possible with traditional manufacturing.

According to industry reports, the global 3D printing medical device market is projected to grow significantly in the coming years, making it a crucial technology for the future of healthcare.

📜 Regulatory Pathway for 3D-Printed Medical Devices

To ensure safety and efficacy, 3D-printed medical devices must comply with strict regulatory standards. Key considerations include:

📌 Material Biocompatibility: Approved materials for medical use.

📌 Sterilization & Quality Assurance: Maintaining hygiene standards.

📌 Device Performance Testing: Ensuring reliability and effectiveness.

📌 Compliance with US FDA, EU MDR, and CDSCO Regulations: Adhering to regional medical device laws.

Manufacturers must demonstrate consistency, reproducibility, and safety in their 3D printing processes to meet these regulatory requirements.

Ready to Bring Your 3D-Printed Medical Device to Life?

How Operon Strategist Can Help

At Operon Strategist, we provide expert solutions to help you establish a successful 3D printing medical device manufacturing unit. Our services include:

✅ Regulatory Compliance Support – Ensuring adherence to global medical device regulations.

✅ Manufacturing Plant Layout Design – Optimized facility setup for efficiency.

✅ Turnkey Project Management – End-to-end solutions from concept to market.

Contact Operon Strategist today and take the next step towards innovation in medical device manufacturing!

FAQs

How is 3D printing being used in the healthcare industry?

In healthcare, 3D printing is used to create personalized surgical tools that match a patient's anatomy precisely. These tools improve the accuracy of procedures involving implants and restorative treatments, leading to better outcomes.

How is 3D printing used in manufacturing?

3D printing revolutionizes manufacturing by producing replacement parts for CNC machines (e.g., tooling, jigs, and assembly fixtures) and optimizing operations with tailored solutions for increased efficiency.

What is an example of medical 3D printing?

Medical 3D printing creates personalized items like joint replacements, cranial implants, and dental restorations. These can be made by big manufacturers or customized directly at the point of patient care, known as point-of-care manufacturing.