The Role of Disposable Medical Equipment in Healthcare

In healthcare, disposable medical equipment plays a vital role in maintaining hygiene and preventing infections. These single-use devices, such as syringes, gloves, face masks, bandages, and surgical sponges, help safeguard patient safety by eliminating the risk of cross-contamination.

Beyond affordability, these medical devices must meet stringent standards for performance, durability, and material quality. With a growing focus on sterility and efficiency, disposable medical equipment is transforming patient care, ensuring safer and more reliable treatments.

Looking For Medical Device Regulatory Consultants?

Disposable Medical Equipment Manufacturing Process

1. Material Selection

- Medical-grade plastics, silicone, or stainless steel ensure safety and durability.

2. Molding & Shaping

- Injection Molding – Used for syringes and connectors.

- Blow Molding – Creates IV fluid bags.

- Extrusion – Produces flexible tubing.

3. Assembly & Bonding

- Ultrasonic Welding – Joins plastic parts.

- Heat Sealing – Used for surgical gowns and masks.

4. Sterilization

- Ethylene Oxide (EtO) Gas – Ideal for plastic tools.

- Gamma Radiation – Sterilizes pre-packaged items.

- Steam Autoclaving – Used for heat-resistant products.

5. Packaging & Quality Control

This process ensures safe, reliable, and high-quality disposable medical equipment for healthcare use. Operon Strategist provides complete Turnkey Project Consultation from Plant Design Layout to the QMS! Connect with Operon to get started!

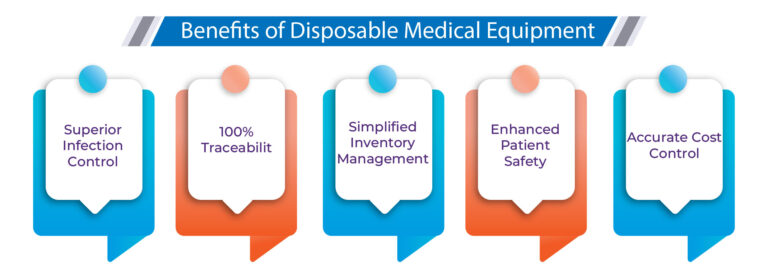

The Game-Changing Benefits of Disposable Medical Equipment

- Superior Infection Control – With pre-sterilized, single-use tools, healthcare professionals eliminate the risk of cross-contamination. No need for complex sterilization—just open, use, and dispose.

- 100% Traceability – Every disposable instrument comes with a lot number, ensuring complete tracking from production to patient use. This minimizes inconsistencies and enhances quality control.

- Simplified Inventory Management – No more worrying about misplaced or damaged tools. Single-use equipment helps healthcare facilities optimize supplies, reducing waste and unnecessary expenses.

- Enhanced Patient Safety – Reusable tools, if not sterilized properly, can spread infections. Disposable medical equipment eliminates this risk, ensuring a safer environment for both patients and medical staff.

- Accurate Cost Control – Unlike reusable tools that have hidden sterilization, maintenance, and labor costs, disposable equipment makes it easy to track expenses for each procedure.

- Eco-Friendly Efficiency – While disposable tools create waste, they actually reduce the environmental footprint by cutting down on water, energy, and chemicals used in sterilization processes.

By switching to disposable medical equipment, healthcare providers can prioritize safety, efficiency, and cost-effectiveness—creating a more reliable and hygienic medical environment.

Operon Strategist: Ensuring Compliance & Quality in Disposable Medical Equipment

Bringing disposable medical equipment to market requires precision, compliance, and efficiency. Operon Strategist simplifies the process with regulatory approvals, manufacturing setup, quality assurance, and post-market support. From FDA & ISO 13485 compliance to cleanroom design and process validation, we ensure a seamless path to market. Trust us for expert guidance and hassle-free approvals—because quality healthcare starts with the right partner!