Disposable Medical Device Manufacturing - An Overview

Disposable medical device manufacturing focuses on producing single-use medical instruments and apparatus designed for one-time use. These devices are commonly utilized in hospitals and healthcare settings and are disposed of after use. According to the FDA, a disposable medical device is intended by the manufacturer for use on a single patient during a single procedure. It is not designed for reuse, has a limited lifespan, and ensures patient safety by preventing cross-contamination.

Looking for Medical Devices Manufacturing Consultant?

Medical device manufacturing needs to comply with rules given by respective regulatory bodies like CDSCO, USFDA etc. while setting up the plant for disposable medical device manufacturing, manufacturing plant layout design is a must. The right design minimizes errors and performs well.

There are numerous types of single-use medical devices, ranging from external, such as plastic gumboots, gloves and bandages merely used to assist a patient to more complex and internal devices, consisting of sharp blades, needles and tubes. Both these devices are Disposable or Single used, because of some reasons, but most importantly when they came in contact with radioactivity, blood infection and disease or the human tissues and must, therefore, be Disposed or terminated.

Each country has its own strict rules and regulations regarding Disposable medical devices and the reprocessing of medical devices in hospitals and clinics. The only reason for creating Disposable medical devices is for infection control. When a medical device is used only once it cannot pass any infectious disease or any infectious agents to subsequent patients. One might think the most important factor in the design of Disposable medical devices manufacturing needs to be careful and balanced between performance, cost, reliability, materials and shelf life.

Plastics are often used in Disposable medical device manufacturing because they are comparatively inexpensive and there are many different types of it. In a medical device such as a syringe that has to sustain extreme pressure, polycarbonates are used because of their strength. PVC Polyvinyl Chloride which is the third most widely produced synthetic polymer after polythene can also be used for its flexibility. On the other hand, Reusable medical devices are more costly materials such as ceramic or steel.

Disposable medical device manufacturing mainly depends mainly on injection moulding plastics which are assembled by bonding, glueing, and ultrasonic welding or radio frequency welding. The high production volume of disposable medical devices calls for automated assembly in clean rooms to avoid human contact. Unlike Reusable device which is frequently sterilized at the healthcare facility, disposable devices are sterilized before leaving the manufacturing site. The medical device design and packaging must be accommodating sterilization.

The reusing or the reprocessing of medical devices labelled as disposable medical devices have been standard practice in U.S. hospitals for years because it makes it less expensive and also reduces material waste. But before the medical devices are being reprocessed or reused a third party or a hospital reprocesses should comply with the same requirements that apply to the original equipment manufacturers according to the US.FDA regulations.

Packaging and Labelling of Disposable Medical Device Manufacturing

For disposable medical devices manufacturing products and all the documentation work appears on the unit packaging. An accurate, detailed and properly formatted package with proper information and instructions to use must be included. Such as content list safety information and instructions for proper disposables.

Why Healthcare Products Should Become More Disposable

Advances in manufacturing and mechanization have diminished the generation cost of numerous products, which has reduced the costs of many products. On the off chance that these trend proceeds, products that are presently viewed as too important to even think about throwing endlessly will turn out to be modest to the point that they will begin to be viewed as disposable. This could incorporate electrical products and complex medical devices or surgical tools. Moreover, when these products are designed explicitly to be single-use or disposables they can be produced using less expensive materials and procedures that will cut the value down considerably more.

Material Selection for Disposable Medical Device Manufacturing

- In some of the applications, these compounds will need certain additives in order to ensure that the properties meet the requirements. For example, Gamma radiation, chemical sterilization resistance etc.

- If the disposable device needs to be printed or labelled the appropriate material should be selected early in the development process it can avoid major difficulties further down the line.

- When selecting the materials for disposable medical devices biocompatibility is the non-transferable requirement. In some cases, these devices are tested for their biocompatibility.

- The texture and grip of these materials can be critical to their suitability.

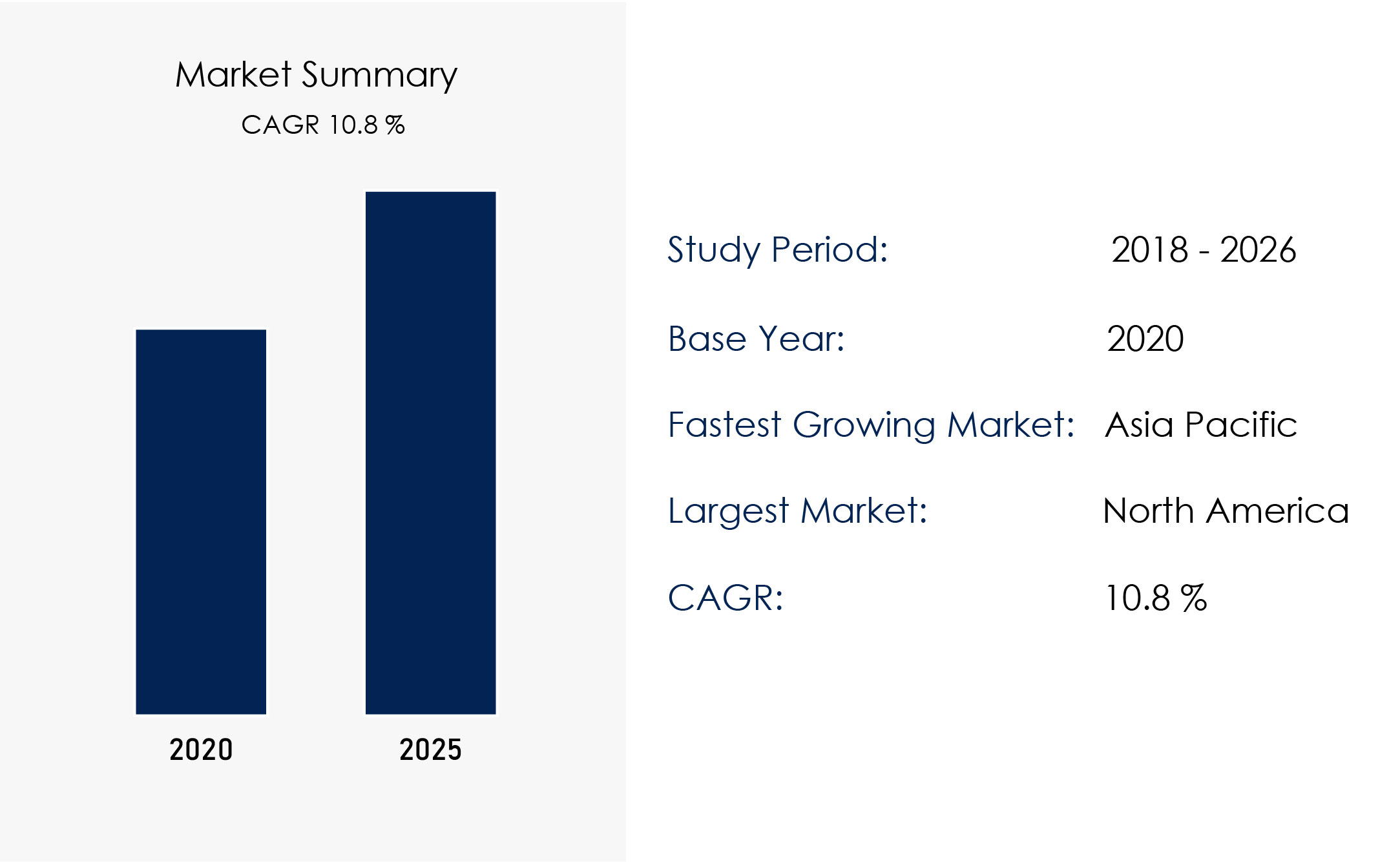

Market Growth for Disposable Medical Device Products

The medical device industry is a multi‐product industry, producing a wide range of products, with varying degrees of capital intensity and multipurpose use. Though it constitutes a very small population in comparison with the total manufacturing sector, in public health its importance is significant. Manufacturing and trade in medical devices are also growing quite steadily over the period of analysis. Disposable medical device manufacturing is becoming more complex and is playing a more important role in the medical device industry. The plan to introduce more disposable products or devices commonly features by setting a low price for the instrument supported by the sale of disposable devices. Operon Strategist medical device regulatory consultancy assists you at every step of your manufacturing process

Role of Operon Strategist

Operon Strategist plays a crucial role in guiding manufacturers through the entire disposable medical device manufacturing process. Our services include:

Regulatory Compliance & Certification – Assisting in meeting global regulatory standards such as US FDA, CE Marking, ISO 13485, and GMP for safe and effective disposable medical devices.

Quality Management System (QMS) Implementation – Developing and implementing QMS to ensure consistent product quality and compliance with industry regulations.

Product Development & Documentation Support – Providing expertise in technical file preparation, design validation, and risk assessment.

Facility Setup & GMP Compliance – Offering guidance in setting up state-of-the-art manufacturing units with adherence to Good Manufacturing Practices (GMP).

Sterilization & Packaging Solutions – Advising on the best sterilization methods and packaging techniques to maintain device integrity.

Audits & Training – Conducting internal audits, supplier audits, and training programs to enhance regulatory awareness and compliance.