US FDA 21 CFR 820.30 Design Control Requirements for Medical Devices in Brazil

When it comes to US FDA 21 CFR 820.30 Design Control, many medical device manufacturers in Brazil face challenges in finding specialized consultants. This is because the regulation is part of the U.S. FDA’s Quality System Regulation (QSR), and much of the expertise is concentrated in the United States. However, international consulting firms like Operon Strategist provide expert support for Brazilian manufacturers aiming to export medical devices to the U.S. market. Our team helps companies in Brazil with implementing FDA-compliant design and development processes, aligning with QSR standards, and preparing the required technical documentation for FDA 510(k) or PMA submissions.

Overview of US FDA 21 CFR 820.30 Design Control Requirements

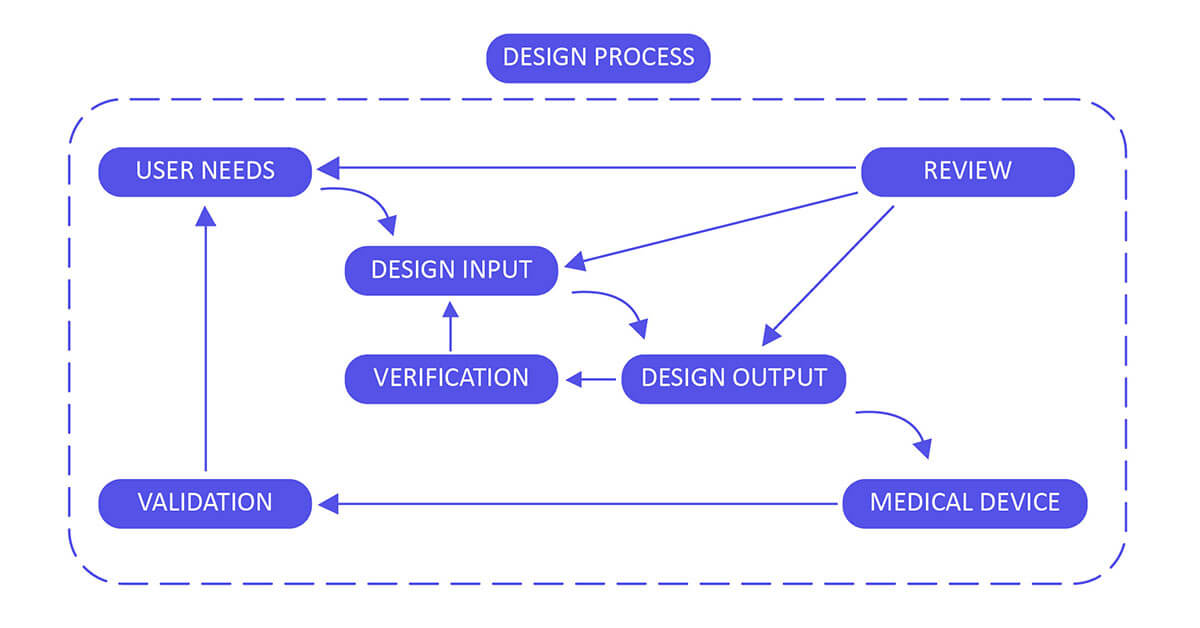

US FDA 21 CFR 820.30 Design Control establishes essential processes to ensure medical devices are developed safely, effectively, and in compliance with regulatory requirements.

For Brazilian manufacturers seeking entry into the U.S. market, it is mandatory to maintain documented design and development processes, including:

- Design inputs and risk management

- Design outputs and technical specifications

- Design reviews and verification

- Design validation and transfer

- Managing design changes

- Maintaining a Design History File (DHF)

Let's Grow Your Business Together

Design Control 21 CFR 820.30 Process for Medical Devices :

Build up and maintain a plan that describes the design and development activities and allocates the individual obligations for each activity. Guarantee you review, update and approve the plan until the device design is completed, verified and validated.

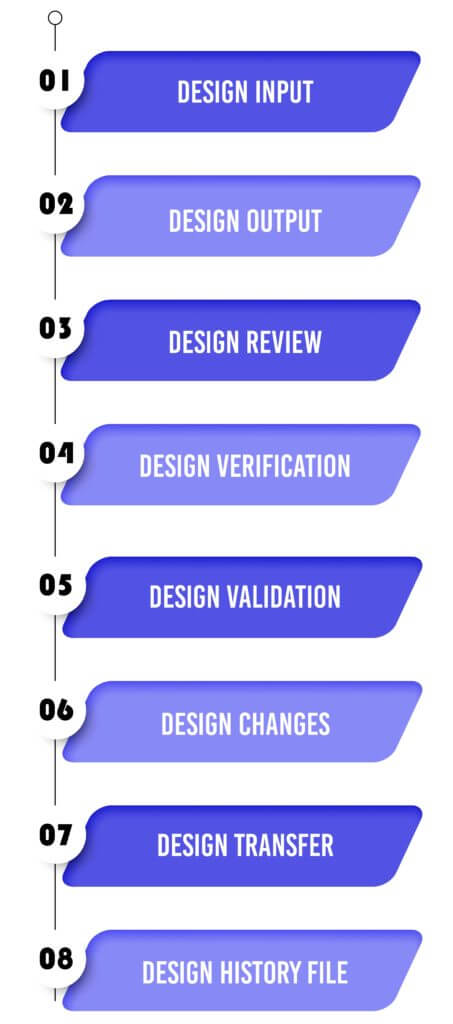

Design Input :

Utilize performance, safety, business economics, outputs of risk management and regulatory requirements as a basis to plan the device with the goal that its motivation and the proposed utilize are clear. The input may also come from surveying your customers( For example, clinicians, nurses, patients).

Design Output :

Design output methods or particulars need to stipulate or refer to the design input document developed by the team and need to identify the critical measures/outputs for the best possible capacity of the device. These incorporate the tests and strategies that may have been produced, adjusted or used to show conformance with the characterized configuration inputs. Examples of design outputs may include:

- The device itself.

- The user manual.

- Specifications A Risk Analysis Study results (For examples, validation and biocompatibility studies, storage).

- Technical Files.

Design Review :

Confirm the design, or identify at an opportune time and right any insufficiencies distinguished at other plan and improvement phases. Two common types of review are hazard analysis, and failure mode and effect analysis.

Design Verification :

Confirm the device outline by means of examination and target prove, verify that the design outputs meet the plan inputs. Design verification activities must be arranged and routinely analyzed and the outcomes must be documented.

Design Validation :

Approve the device design plan by means of examination and target prove, affirm that the last outline yield reliably meets the particular planned utilize. Design validation should follow successful design verification. Since outline check is directed while the plan work is being performed, design validation confirms that the medical device meets its intended use. Generally, this is set up through in vitro execution, practical testing, creature testing and additionally in vivo clinical assessments and trials.

Design Changes :

Guarantee that all plan changes are distinguished, documented, approved, verified, reviewed and endorsed before usage.

Design Transfer :

Ensure that the design of the medical device can be correctly translated into production specifications (that is, advancing successfully from product development to manufacturing).

Ready to take your medical device to the U.S. market?

Operon Strategist’s Role in Supporting Brazilian Manufacturers

At Operon Strategist, we specialize in consulting for US FDA 21 CFR 820.30 Design Control in Brazil. Our services include:

- Developing FDA-compliant design and development processes

- Bridging gaps between ISO 13485:2016 and FDA QSR

- Preparing documentation for 510(k) and PMA submissions

- Training teams in verification, validation, and DHF management

We help Brazilian manufacturers strengthen compliance, minimize risks, and achieve faster approval in the U.S. market.

FAQ'S

What is US FDA 21 CFR 820.30 Design Control?

It is a regulation under the FDA’s Quality System Regulation (QSR) that defines design and development requirements for medical devices, ensuring safety and compliance.

Is compliance with 21 CFR 820.30 mandatory for Brazilian manufacturers exporting to the U.S.?

Yes. Any manufacturer in Brazil that wants to sell medical devices in the U.S. must comply with FDA QSR, including design controls.

How does design control impact FDA approval?

Strong design controls reduce risks of rejection, ensure safety, and create the documentation trail required for 510(k) or PMA approval.

Do ISO 13485 design controls fulfill FDA 21 CFR 820.30 requirements?

While ISO 13485 is closely aligned with FDA QSR, it is not identical. Operon Strategist helps Brazilian manufacturers comply with both standards.

What is a Design History File (DHF), and why is it important?

A DHF is a collection of documents that prove a device was designed according to FDA requirements. It is essential during inspections and submissions.