Medical Device Product Feasibility & Detail Project Report

Market Analysis and Feasibility for Medical Devices In Germany

Market analysis and feasibility studies are the cornerstone of any successful medical device product development cycle. At Operon Strategist, we understand the importance of evaluating client needs, characterizing the product, and identifying the right strategies to bring innovative medical devices to life.

From defining the regulatory pathway to implementing a robust Quality Management System (QMS) with risk management and executive planning, every step is critical. Product design concepts are meticulously assessed to ensure clinical utility while estimating costs for efficient market entry.

Your Trusted Partner in Regulatory Advisory

Operon Strategist is a trusted regulatory consulting company, offering expert guidance to healthcare manufacturers. We provide strategic solutions that drive the development and commercialization of medical devices tailored to meet Germany’s high regulatory standards.

About Market Research, Market Analysis and Feasibility for Medical Devices.

Market research goes beyond numbers. It’s about understanding cultural preferences, pricing disparities, and the unique characteristics of international markets, including Germany. Here’s why it matters:

- Cultural Insights: Certain cultures may favor or reject specific medical procedures or devices.

- Target Market Size: A small target market might indicate limited potential; identifying this early saves resources.

- International Market Complexity: While existing data helps gauge local markets, global market insights, especially for Germany, require in-depth research and feasibility studies.

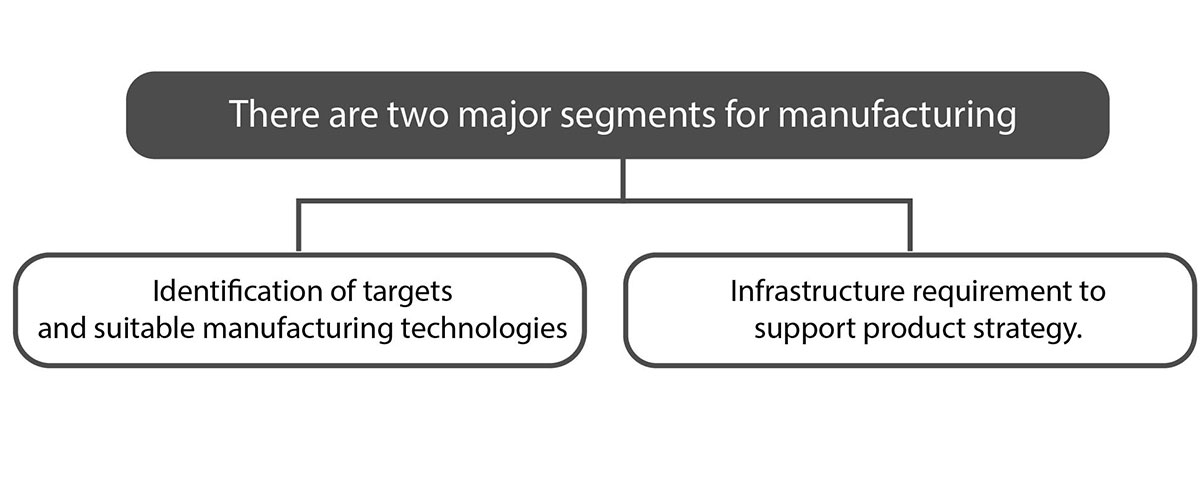

Key Segments in Medical Device Manufacturing

a) Electrical Devices

Examples: ECG machines, pulse oximeters, and X-rays.

b) Disposable Devices

Examples: Syringes, masks, IV cannulas, and IV sets.

Depending on the segment, specialized expertise is required, whether in electronics or materials like plastic for disposable products.

1) Identification of targets and suitable manufacturing technologies

Medical device manufacturers strive to be more efficient and fast in their manufacturing processes, while also being responsible corporate citizens. Thus, manufacturing demands constant insight into renewable resources, sustainable materials, equipment that is more energy efficient, suitable manufacturing technologies, and methods to reduce waste creation.

2) Infrastructure requirement to support product strategy

Early development encompasses fundamental steps such as the definition of the device specifications, foreseen intended uses and indications for use, and the gathering of relevant data to support product safety for market and feasibility studies. A thorough risk analysis is performed to support the product’s global development plan. The infrastructure is dependent on the location of manufacturing and the intended market. Particularly when it comes to serializable and disposable products.

Why Choose Operon Strategist for Market Feasibility in Germany?

- Expert Guidance: Decades of experience in regulatory pathways and market entry strategies.

- Tailored Solutions: Customized plans for manufacturers in Germany’s healthcare market.

- Global Perspective: Insights into both local and international market demands.

Ready to Turn Your Vision into Reality?

Contact Operon Strategist today at enquiry@operonstartegist.com or you can WhatsApp us and let us guide your medical device development journey in Germany with precision and expertise.

FAQ'S

A product feasibility study evaluates the practicality of a proposed product by analyzing technical, financial, operational, and legal aspects. It helps companies make informed decisions on whether to pursue a project.

It provides a comprehensive analysis of project goals, resource requirements, potential risks, and expected benefits, ensuring the project has the highest chance of success.

Operon Strategist offers a complete feasibility analysis, including market research, technical evaluation, financial assessment, legal compliance check, and preparation of a detailed project report.

The timeline varies depending on the complexity of the project, but typically it ranges from 4 to 8 weeks.

Operon Strategist provides tailored solutions specific to your project’s needs, ensuring all critical factors are thoroughly analyzed for successful project execution.