Introduction to Disposable Syringe Manufacturing:

Did you know that Oman’s healthcare sector is rapidly growing, creating a demand for high-quality medical devices like disposable syringes? Oman’s medical device manufacturing industry presents lucrative opportunities for businesses looking to set up manufacturing units.

In this guide, we’ll explore:

- The manufacturing process of disposable syringes

- The raw materials required

- Regulatory compliance and approval process

- Challenges and how to overcome them

Let’s dive into establishing a successful syringe manufacturing unit in Oman!

Looking For a Medical Device Regulatory Consultant?

Let’s have a word about your next project

1. Understanding Disposable Syringes

A disposable syringe is a single-use medical device used for injecting or withdrawing fluids. These syringes are widely used in:

- Hospitals & clinics

- Diagnostic labs

- Vaccination programs

- Home healthcare

Types of Disposable Syringes

- Luer Lock Syringes – Ensures a secure needle fit

- Luer Slip Syringes – Quick needle attachment

- Insulin Syringes – Used for diabetes care

- Safety Syringes – Prevent needle-stick injuries

The global disposable syringe market is growing at a CAGR of 5.6%, making it a profitable sector to invest in!

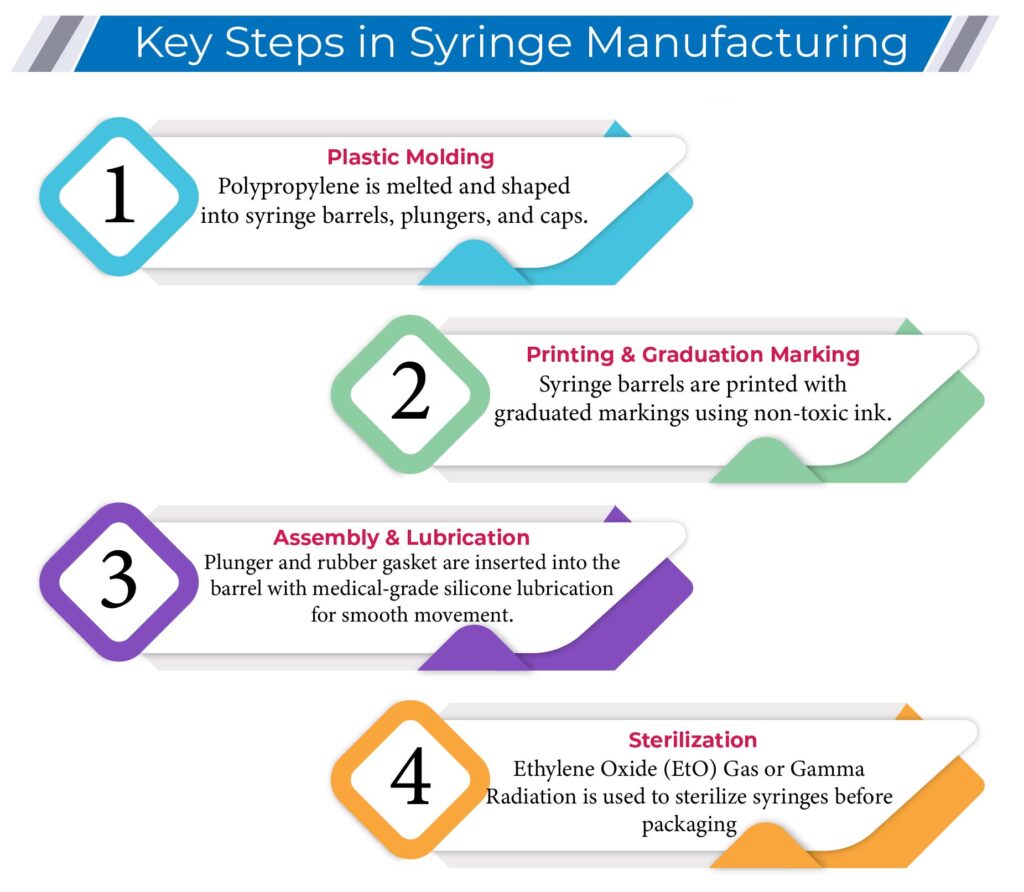

2. Key Steps in Syringe Manufacturing

3. Raw Materials & Equipment Required

Raw Materials

- Polypropylene (PP) – For barrels and plungers

- Rubber Gaskets – Ensures a secure plunger seal

- Medical-Grade Lubricant – For smooth syringe operation

- Needles & Stainless-Steel Cannulas

Essential Machinery

- Injection Molding Machine

- Printing Machine

- Assembly Line

- Sterilization Chamber

💡 Choosing high-quality raw materials improves product durability and compliance.

4. Regulatory Compliance in Oman

Manufacturers must comply with Oman’s Ministry of Health (MOH) regulations and international standards such as:

- ISO 13485:2016 – Quality Management System for medical devices

- ISO 10993 – Biocompatibility of medical devices

- GMP (Good Manufacturing Practices) compliance

- Import & Registration Requirements under Oman’s MOH

📌 Regulatory approval is crucial for exporting syringes to international markets like the GB, EU, US, and more.

5. Challenges & Solutions

Challenges

❌ High Initial Investment – Machinery & facility setup costs

❌ Regulatory Hurdles – Compliance with MOH & international standards

❌ Competition – Competing with established global brands

Solutions

✅ Financial Planning & Grants – Government incentives for local manufacturers

✅ Regulatory Consultants – Hiring experts like Operon Strategist for regulatory guidance

✅ Advanced Technology – Investing in automated production for cost efficiency

Overcoming these challenges can make Oman a key player in the syringe manufacturing sector!

Need Expert Guidance for Setting up a Syringe Manufacturing Unit in Oman?

6. Conclusion

✅ Oman’s syringe manufacturing industry is a promising venture with a growing demand in the healthcare sector.

✅ Following regulatory guidelines ensures compliance and export opportunities.

✅ Investing in high-quality materials and advanced technology enhances competitiveness.

🔴 Need help with regulatory approvals? Contact Operon Strategist for expert consultation!

What challenges do you foresee in setting up a syringe manufacturing unit?