IOL Cast Molding Technology: Transforming Intraocular Lens Manufacturing in Oman

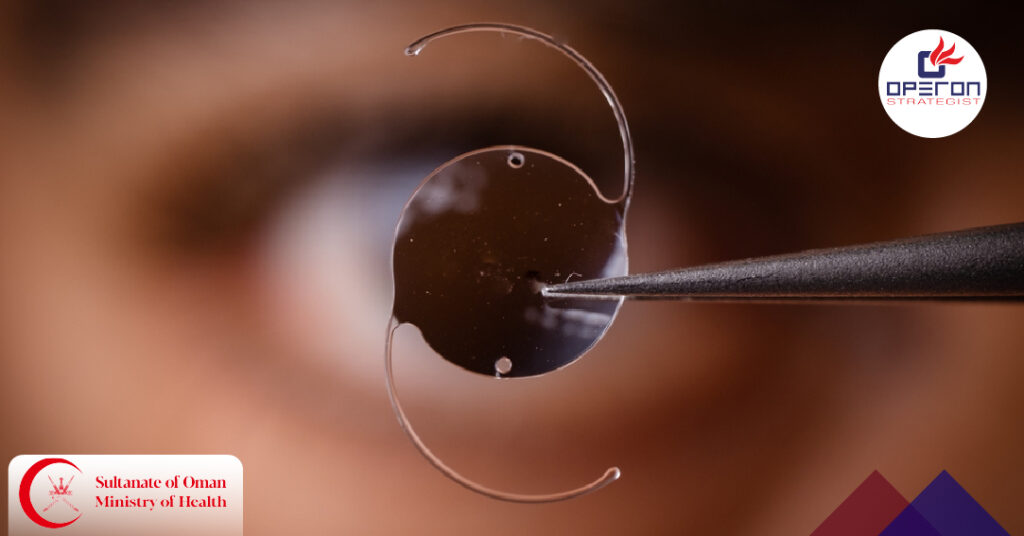

IOL Cast Molding Technology is revolutionizing intraocular lens (IOL) manufacturing worldwide — and Oman is no exception. With cataract surgeries increasing in the region and growing demand for premium vision correction, ophthalmic device manufacturers are adopting cast molding to ensure precision, repeatability, and compliance with strict medical standards.

Unlike traditional lathe-cut methods, cast molding allows high-volume production of advanced IOLs including toric, multifocal, and aspheric lenses. This method not only improves quality but also accelerates market readiness.

Looking for Medical Device Manufacturing Consultant

Why Oman Manufacturers Should Consider IOL Cast Molding Technology

Oman’s healthcare sector is expanding, driven by government initiatives to improve eye care services. Local manufacturers can benefit from:

- Scalable Production: Efficiently produce large volumes of IOLs to meet rising demand.

- Premium Lens Designs: Support for multifocal, toric, and aspheric lenses.

- Regulatory Compliance: Meet Oman MOH medical device regulations with proper documentation and quality systems.

- Faster Time to Market: Streamlined processes reduce production costs and approval timelines.

Partnering with a medical device regulatory consultant ensures your IOL products meet local and international standards while entering the market confidently.

What is IOL Cast Molding Technology?

IOL Cast Molding is a process where liquid polymer is injected into precision molds and cured to form intraocular lenses. The process ensures:

- Consistent lens geometry

- High surface quality

- Minimal material waste

It is ideal for producing IOLs from hydrophobic and hydrophilic acrylic polymers, which require tight optical tolerances and biocompatibility.

Step-by-Step IOL Cast Molding Process

Design & Fabrication of Molds

High-precision molds are crafted to define optical power and lens curvature.Polymer Preparation

Medical-grade polymers are enhanced with UV initiators for clarity and durability.Injection into the Mold

Controlled injection ensures bubble-free, defect-free lenses.Curing (UV/Thermal)

Polymers are cured to achieve solid, stable lens properties.Lens Removal & Polishing

Lenses are demolded, polished, and edge-finished to meet surgical standards.Final Quality Checks

Each lens undergoes optical, visual, and dimensional inspection before packaging and sterilization.

Advantages of IOL Cast Molding

- Unmatched Reproducibility: Consistent lenses for patient safety.

- Superior Surface Finish: Minimizes light scattering, enhancing post-operative vision.

- Support for Complex Designs: Enables multifocal and toric lenses.

- Faster Market Entry: Efficient automation and material use reduce costs.

- Compliance-Ready: Controlled and validated processes simplify CDSCO, EU MDR, FDA 510(k), and Oman MOH regulatory compliance.

Market Growth Driving Adoption

Global and regional demand for IOLs is increasing due to:

- Aging population and rising cataract prevalence

- Growth in premium IOL adoption

- Increase in refractive surgeries in the Middle East

- Government healthcare initiatives improving eye care accessibility

Manufacturers investing in cast molding technology are positioned to meet this demand efficiently and cost-effectively.

Regulatory Requirements for IOL Manufacturing in Oman

IOLs are Class C or Class III medical devices in most regulatory frameworks. In Oman:

- MOH Medical Device Registration: Required for all ophthalmic devices

- ISO 13485 Compliance: Quality management system for safe production

- Technical Dossier Submission: Includes performance, safety, and clinical data

Consultants can guide manufacturers through technical documentation, quality system setup, and regulatory filing to ensure smooth MOH approvals.

Need help setting up your IOL manufacturing unit in Oman?

How Operon Strategist Supports IOL Manufacturers in Oman

Operon Strategist offers end-to-end consulting for companies setting up IOL cast molding facilities:

- Turnkey manufacturing plant design and cleanroom setup

- ISO 13485:2016 implementation

- Regulatory filing for Oman MOH, CDSCO, CE, and FDA 510(k) approvals

- Documentation for technical files, clinical evaluation, and product dossiers

- Process validation, labeling, and sterilization support

Whether you are a startup or an established manufacturer, our experts ensure compliant, scalable, and high-quality IOL production.

FAQs

What is IOL Cast Molding Technology and why is it important?

IOL Cast Molding Technology is a manufacturing method where liquid polymer is injected into precision molds to produce high-quality intraocular lenses. It is important because it offers superior accuracy, consistent lens geometry, and higher production efficiency compared to traditional methods.

How does IOL Cast Molding Technology improve IOL quality?

This technology ensures a smooth surface finish, reduces optical defects, and delivers highly reproducible lens shapes. The precise molding process enhances clarity, biocompatibility, and long-term visual outcomes for patients.

Is cast molding suitable for all types of IOLs?

Yes. Cast molding supports a wide range of advanced IOL designs including monofocal, multifocal, toric, and aspheric lenses. It is ideal for both hydrophobic and hydrophilic acrylic materials commonly used in modern IOLs.

What regulatory requirements apply to cast-molded IOL manufacturing?

IOL manufacturers must comply with regulations like ISO 13485, CDSCO Class C requirements, EU MDR Class III, and FDA 510(k) or PMA pathways. Cast molding helps meet these requirements through controlled, validated, and repeatable processes.

Why should manufacturers in Oman adopt IOL Cast Molding Technology?

Manufacturers in Oman benefit from this technology due to its scalability, lower production cost, faster time-to-market, and ability to meet stringent Ministry of Health (MOH) and international regulatory standards—making it ideal for both local and global distribution.