Manufacturing Plant Facility Layout Design Consultant in Oman

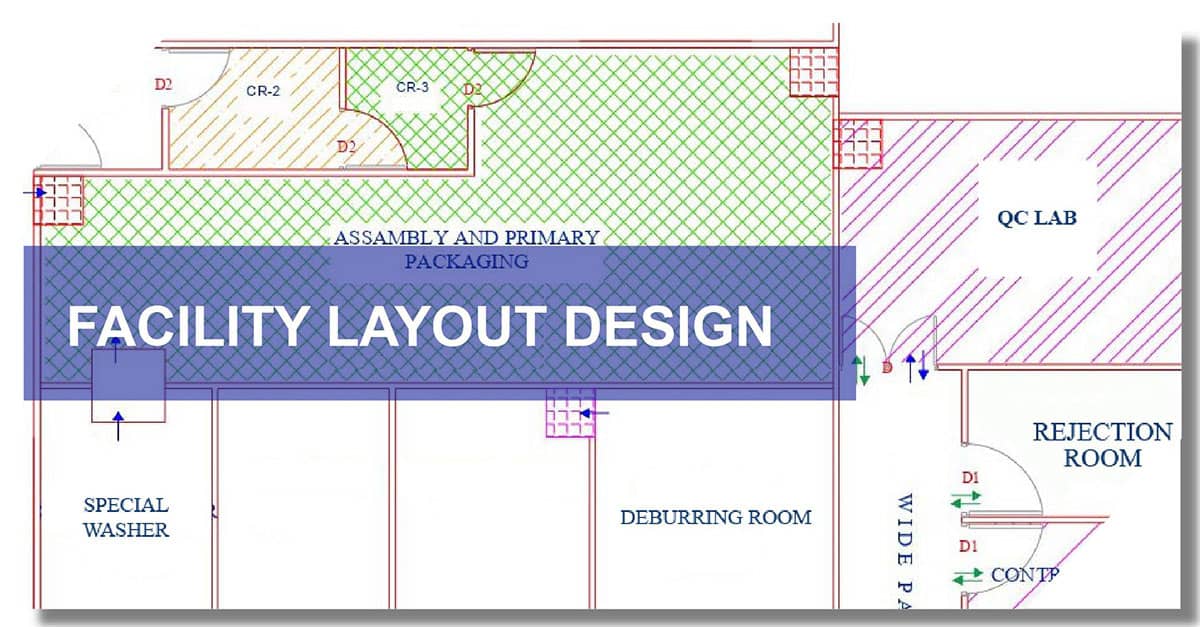

Setting up a manufacturing plant layout design in Oman is the first and most crucial step for medical device companies. A well-planned facility layout not only ensures regulatory compliance but also drives operational efficiency, safety, and productivity. In Oman’s growing medical device and pharmaceutical sector, compliance with US FDA, CDSCO, CE Marking, SFDA, and GCC standards is essential to compete in both local and international markets. If you manufacture orthopedic implants, disposable devices, packaging materials, or pharmaceutical products, your facility must meet GMP (Good Manufacturing Practices) and global regulatory requirements to support successful US FDA 510(k) clearance and long-term market access.

The Blueprint for Success

Streamlined Material & Workflow Design – Prevent mix-ups and ensure smooth operations.

Dedicated Segregation Zones – Minimize cross-contamination risks and maintain product quality.

Cleanroom-Ready Classified Areas – Meet international cleanroom design standards for medical devices.

Logical Process Flow – Reduce bottlenecks and optimize production efficiency.

Step-by-Step Process for Medical Device Plant Layout Design

- Understand Your Manufacturing Process – Analyze all production steps.

- Map Out Workflow – Build a layout around process flow to minimize delays.

- Ensure Compliance – Align design with US FDA, CE Marking, SFDA, and Oman’s regulations.

- Strategic Layout Design – Plan for space optimization, material flow, and scalability.

- Safety & Ergonomics – Prioritize team well-being and safety infrastructure.

- Collaborate with Experts – Work with layout consultants, architects, and engineers.

- Evaluate & Improve – Continuously audit layout for efficiency and regulatory readiness.

Let’s Connect! Your Queries, Our Expertise!

Advantages of Professional Manufacturing Plant Layout Design Services

Seamless Compliance – Align with global standards like US FDA, CE Marking & GMP.

Optimized Efficiency – Reduce downtime and maximize throughput.

Boosted Productivity – Faster cycles with superior quality output.

Uncompromised Safety – Protect staff and maintain product integrity.

Enhanced Quality Control – Robust systems for consistent performance.

Partner With Us for Expert Plant Layout Design Services in Oman

At Operon Strategist, our team of experienced engineers, regulatory consultants, and quality assurance experts supports the design and development of fully compliant medical device manufacturing facilities in Oman. From concept to completion, we ensure your facility meets ISO 13485, Oman Ministry of Health (MoH), US FDA, and CE Marking requirements, enhancing operational efficiency, audit readiness, and global market access while supporting regulatory pathways such as US FDA 510(k) clearance.

Transform your medical device facility in Oman with expert plant layout design.

Why Choose Operon Strategist for Manufacturing Plant Layout Design in Oman?

Local & Global Expertise: Deep understanding of Oman’s regulatory landscape combined with international compliance standards.

Strong Regulatory Knowledge: Facility layouts aligned with US FDA, CE Marking, ISO 13485, and local GMP requirements, supporting approvals such as US FDA 510(k).

Tailored Layout Designs: Customized manufacturing plant layouts based on product type, process flow, cleanroom classification, and available space.

Comprehensive Review & Gap Analysis: Identification of layout inefficiencies, compliance gaps, and opportunities for process optimization.

End-to-End Support: Complete assistance from concept planning and detailed layout design to execution and regulatory readiness.

Proven Operational Gains: Improved productivity, enhanced safety, faster output, and reduced regulatory and compliance risks.

FAQs

What is Manufacturing Plant Layout Design and why is it important?

A manufacturing plant layout design is the strategic arrangement of equipment, workflows, and spaces inside a facility to maximize efficiency and reduce costs. A well-planned design helps manufacturers improve productivity, meet compliance standards, and avoid unnecessary operational delays.

How does a good plant layout design improve productivity?

A smart layout reduces material handling time, ensures smooth workflow, and minimizes bottlenecks. This directly leads to faster production, lower downtime, and higher output—helping companies stay competitive.

What factors should be considered while designing a manufacturing plant layout?

Key factors include workflow efficiency, regulatory compliance (like ISO, GMP), safety requirements, cleanroom needs, space utilization, and future scalability. Considering these from the start saves cost and rework.

Do I need a consultant for plant layout design?

Yes, working with expert consultants ensures your facility meets both regulatory standards and operational efficiency. Consultants bring practical experience, industry insights, and compliance knowledge that reduces project risks.

How can Operon Strategist help in Manufacturing Plant Layout Design?

Operon Strategist provides turnkey plant layout design consulting—from feasibility reports to regulatory approvals. Our experts create layouts tailored to your production needs, ensuring compliance with global standards while reducing time-to-market.