Surgical Bandage Manufacturing Plant Setup: An Overview

With the rising demand for quality healthcare supplies in the Middle East, setting up a surgical bandage manufacturing plant in Oman presents a promising opportunity for investors and manufacturers. The country’s expanding healthcare infrastructure and government initiatives to boost local medical device manufacturing make it an ideal destination for surgical bandage production. However, understanding the regulatory framework and establishing a compliant manufacturing plant is essential for successful market entry.

Want to take your surgical bandage manufacturing project to the next level? Contact Operon Strategist today for expert guidance on manufacturing plant layout design and turnkey solutions that can transform your stent manufacturing project.

Looking For a Medical Device Regulatory Consultant?

Why Invest in Surgical Bandage Manufacturing in Oman?

Oman’s healthcare sector is witnessing significant growth due to population expansion, increasing medical needs, and government investment in public and private hospitals. Surgical bandages are essential consumables across all healthcare facilities, and currently, a significant portion is imported. This opens a gap for domestic manufacturing of surgical bandages to meet national demand and reduce import dependency.

Key Opportunities:

- Rising demand for surgical consumables across public and private hospitals

- The government pushes for local medical device manufacturing

- Free Trade Agreements (FTAs) and access to the Gulf Cooperation Council (GCC) market

Types of Surgical Bandages You Can Manufacture

To cater to a broad market, your manufacturing plant in Oman can produce a variety of surgical bandages, such as:

- Gauze Bandages

- Adhesive Bandages

- Compression Bandages

- Triangular Bandages

- Liquid Bandages

- Tubular Bandages

Each type has unique uses in wound care, support, and surgical dressing applications.

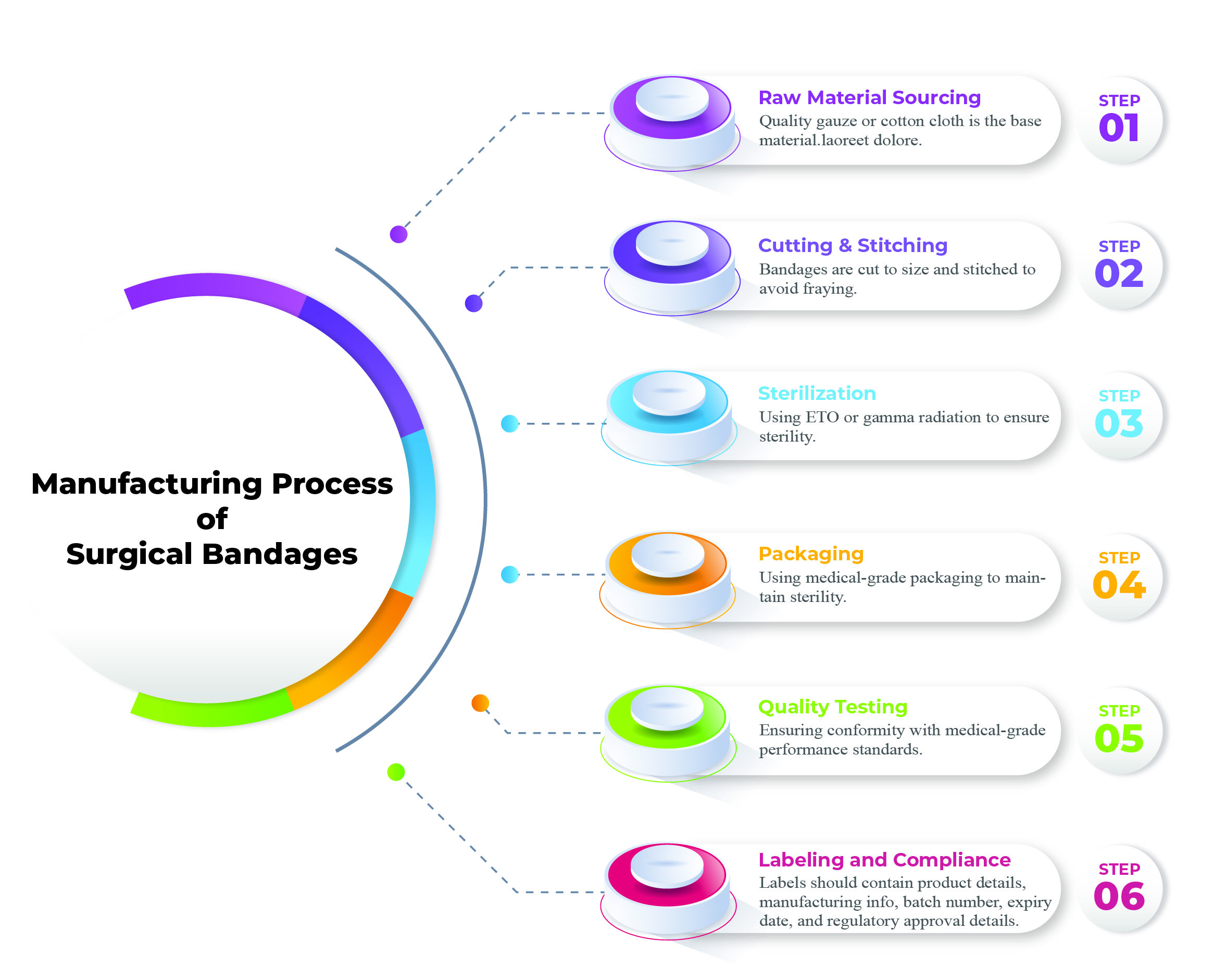

Manufacturing Process of Surgical Bandages

The basic surgical bandage manufacturing process includes:

Raw Materials Required

To begin operations, you’ll need to procure and manage the following materials:

- White bleached cotton gauze

- Non-stick pads

- Adhesive materials

- Sterilization agents (ethylene oxide, gamma ray)

- Plastic film and paper for packaging

- Colorants/dyes (if applicable)

Regulatory Compliance for Medical Devices in Oman

In Oman, medical devices, including surgical bandages, fall under the regulatory purview of the Department of Pharmacy and Drug Control at the Ministry of Health (MoH).

Key Regulatory Requirements:

- Product Registration with the Ministry of Health (MoH), Oman

- Submit product dossier

- Provide evidence of quality and safety (clinical data, manufacturing standards, etc.)

- Free Sale Certificate (FSC)

- Usually required from the country of origin

- Usually required from the country of origin

- ISO 13485 Certification

- The QMS standard mandatory for medical device manufacturing facilities

- The QMS standard mandatory for medical device manufacturing facilities

- Labeling Requirements

- Must include Arabic and English instructions, usage info, manufacturer details, expiry, and lot number

- Must include Arabic and English instructions, usage info, manufacturer details, expiry, and lot number

- Import Permit (for initial raw materials or equipment)

Required before bringing manufacturing machines or inputs into Oman

Quality & Certification Standards

Manufacturers must comply with:

- ISO 13485:2016 – Medical Device Quality Management System

- GMP (Good Manufacturing Practices) for cleanliness and traceability

- Sterilization validations based on ISO 11135 (for ETO) or ISO 11137 (for Gamma)

- Product safety testing including biocompatibility and absorbency standards

Steps to Set Up a Surgical Bandage Manufacturing Plant in Oman

- Market Research & Feasibility Report

- Analyze market size, competition, and business model

- Analyze market size, competition, and business model

- Business Registration

- Register the company in Oman through the Ministry of Commerce, Industry & Investment Promotion (MOCIIP)

- Register the company in Oman through the Ministry of Commerce, Industry & Investment Promotion (MOCIIP)

- Location & Facility Setup

- Choose a compliant industrial zone with utilities and export access

- Choose a compliant industrial zone with utilities and export access

- QMS Implementation (ISO 13485)

- Establish SOPs, documentation, validation, and training protocols

- Establish SOPs, documentation, validation, and training protocols

- Equipment Procurement & Installation

- Surgical bandage cutting, rolling, and packaging machines

- Surgical bandage cutting, rolling, and packaging machines

- Hire Qualified Staff

- Operators, QA/QC specialists, and regulatory professionals

- Operators, QA/QC specialists, and regulatory professionals

- Regulatory Filing with MoH Oman

- Submit product dossier, company documents, and quality certifications

- Submit product dossier, company documents, and quality certifications

- Start Trial Production & Compliance Testing

- Validate manufacturing and sterilization processes

- Validate manufacturing and sterilization processes

- Begin Full-Scale Manufacturing

- Distribute domestically and export to other GCC countries

- Distribute domestically and export to other GCC countries

Export Potential to GCC and Beyond

Oman’s strategic location makes it a hub for exporting surgical bandages to:

- UAE, Saudi Arabia, Bahrain, and Qatar (within GCC, with minimal trade barriers)

- African countries with emerging healthcare infrastructure

- South Asia, given proximity and existing trade ties

Obtaining regulatory clearances, such as CE Marking or a US FDA 510(k) clearance, can help further expand exports.

Ready to Start Your Surgical Bandage Manufacturing Plant in Oman?

How Operon Strategist Helps

At Operon Strategist, we support businesses across all stages of setting up a surgical bandage manufacturing plant in Oman, including:

✅ Feasibility study & project report

✅ ISO 13485 QMS implementation

✅ Regulatory submissions for Oman MoH, FDA, CE marking, and SFDA approval

✅ Turnkey plant setup – layout, machine sourcing, installation

✅ Product testing & validation protocols

✅ Staff training and documentation support