How Medical Gloves Are Manufactured: A Step-by-Step Guide

Medical gloves are vital tools in infection control, acting as a protective barrier between healthcare providers and patients. Whether used in surgeries, examinations, or laboratory settings, these gloves must meet stringent quality and regulatory standards to ensure safety and hygiene.

In this detailed guide, we walk you through the step-by-step manufacturing process of medical gloves from raw material selection to final inspection. You’ll also learn about the critical role of quality control and how Operon Strategist can support manufacturers in achieving full regulatory compliance and market readiness.

Looking for Medical Device Regulatory Consultant?

Elevate your medical glove manufacturing project with Operon Strategist. Contact us today for expert guidance on manufacturing plant layout design and turnkey solutions to transform your glove production process.

Why Medical Gloves Are Essential

Medical gloves are indispensable in healthcare, protecting both patients and professionals from cross-contamination and pathogen exposure.

🔹 Prevent infections: The World Health Organization (WHO) recommends gloves to reduce the spread of diseases.

🔹 Enhance safety: Gloves act as a physical barrier against bodily fluids and harmful chemicals.

🔹 Regulatory compliance: All gloves must meet strict quality standards like ISO 13485, CE marking, and USFDA 510(k) clearance.

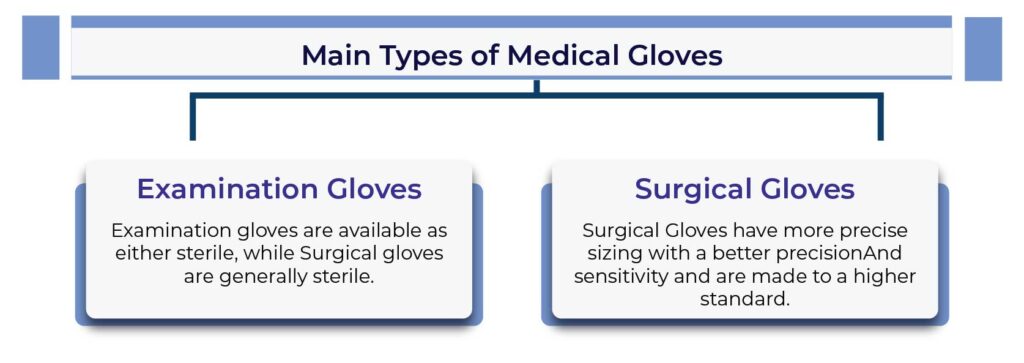

Types of Medical Gloves

Medical gloves are classified based on material and usage:

- Examination Gloves: Used by doctors, nurses, and lab technicians for routine check-ups.

- Surgical Gloves: Designed for precision and sterility during surgeries.

Materials Used:

- Latex (High elasticity but may cause allergies)

- Nitrile (Allergy-free, chemical-resistant)

- Vinyl (Affordable, low durability)

Step-by-Step Manufacturing Process

1️⃣ Mold Preparation

- Ceramic or aluminum molds shaped like hands are thoroughly cleaned.

- Molds are sterilized to ensure no contamination.

2️⃣ Coating Application

- Molds are dipped into a solution of calcium nitrate & calcium carbonate.

- This layer helps the glove material adhere smoothly.

3️⃣ Drying

- Coated molds are dried to remove excess moisture.

- Ensures proper glove thickness and adhesion.

4️⃣ Material Dipping

- Molds are dipped into latex, nitrile, or PVC.

- Dipping time determines the glove thickness.

5️⃣ Excess Removal and Washing

- Excess material is spun off for uniform thickness.

- Gloves are washed with hot water & chlorine to remove residues.

6️⃣ Vulcanization and Curing

- Gloves are heated in an oven or autoclave to strengthen the material.

- This step enhances durability and elasticity.

7️⃣ Quality Control and Testing

- Each batch undergoes rigorous testing, including:

- Leakage and puncture tests

- Tensile strength measurement

- Fit and sizing inspection

8️⃣ Beading and Cuffing

- Edges of gloves are rolled to create a cuff for easy wear.

- Ensures a secure fit during medical procedures.

9️⃣ Stripping and Packaging

- Gloves are removed manually or via automated machines.

- They are then sterilized and packed for distribution.

Ready to Launch Your Medical Glove Manufacturing Business?

How Operon Strategist Helps Medical Glove Manufacturers

🔹 Regulatory Compliance Assistance: We help manufacturers obtain necessary certifications such as CDSCO, USFDA 510(k), UKCA, and CE Marking.

🔹 Manufacturing Plant Setup: We provide turnkey project solutions for medical glove production.

🔹 Quality System Implementation: Guidance on ISO 13485 compliance and GMP (Good Manufacturing Practices).

Ready to Transform Your Glove Manufacturing Business? Get expert regulatory guidance today! Contact Operon Strategist to optimize your medical glove manufacturing and ensure compliance with global standards.