How to Get CE Mark For Medical Devices: An Overview

Getting a CE mark for medical devices an be a complex process, involving stringent regulatory requirements. This guide provides a comprehensive overview of the steps involved in getting CE mark approval for medical devices, aiming to facilitate understanding and compliance with the Europe medical devices regulation MDR CE marking regulatory process.

While this guide offers valuable insights, it is essential for medical device manufacturers to refer to the MDR for complete and up-to-date information. Many companies choose to hire consulting firms to navigate the CE marking process for medical devices due to the complexity and recent MDR implementation, which has increased demand for these professionals.

Also read our service page on: CE Mark Medical Device (EU MDR) Consultant

Looking For a CE Mark Medical Device Consultant?

Let’s have a word about your next project

Why CE Marking Matters

The CE mark medical device certification is a certification mark that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). For medical devices, the CE mark certification demonstrates compliance with the MDR, ensuring that the devices are safe and effective for use.

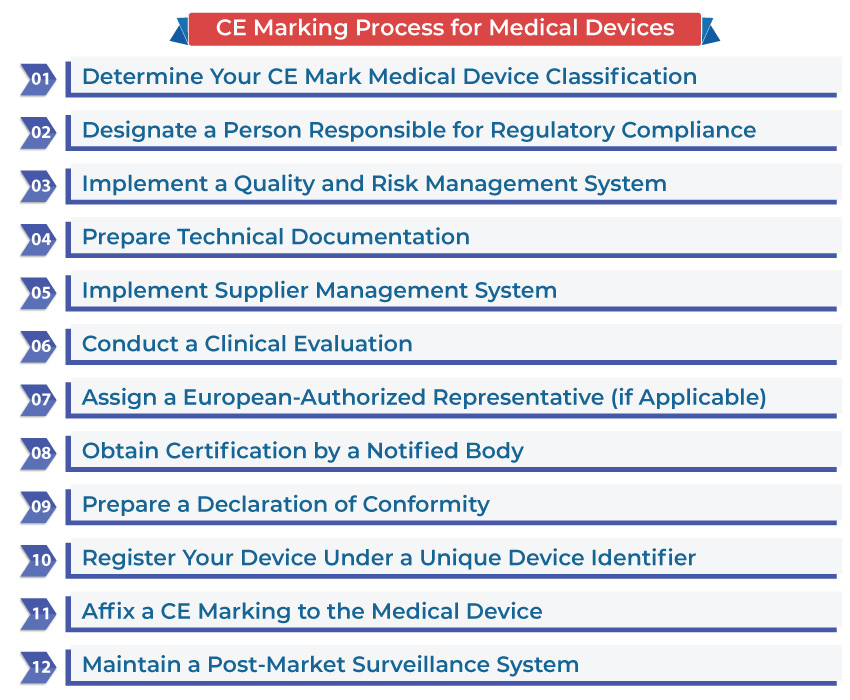

Detailed Steps for Obtaining CE Mark Certification for Medical Devices

1. Determine Your CE Mark Medical Device Classification

The MDR classifies medical devices based on their risk level, body placement, and duration of use:

- Risk Level: Devices are classified into four classes: I, IIa, IIb, and III, with Class III representing the highest risk.

- Body Placement: Devices can be non-invasive (on the body’s surface) or invasive (inside the body). Active devices rely on an external energy source.

- Duration of Use: Devices are classified based on their usage duration: transient (up to 60 minutes), short-term (up to 30 days), and long-term (over 30 days).

For example, an X-ray machine is a non-invasive, active Class II device, while a pacemaker is an invasive, active Class III device.

Also Read: Medical Device Classification in Europe

2. Designate a Person Responsible for Regulatory Compliance

Manufacturers must appoint a person responsible for regulatory compliance (PRRC) with expertise in medical devices. For smaller organizations, this individual does not need to be on-site but must be available continuously.

Also Read: EU MDR Economic Operator & EU Authorized Representative

3. Implement a Quality and Risk Management System

The MDR requires manufacturers to have a quality management system (QMS) and a risk management system. ISO 13485:2016 is the preferred standard for QMS compliance.

4. Prepare Technical Documentation

Technical documentation, or technical files, must detail the medical device lifecycle and demonstrate compliance with MDR. This includes:

- Device description and specification

- Accessory and variation descriptions

- Instructions for use in the country’s language

- Design and manufacturing information

- Risk analysis documents

- Product verification and validation

- Post-market surveillance plan

Also Read: Medical Device Technical Documentation for MDR

5. Implement Supplier Management System

Manufacturers must audit suppliers to ensure compliance with MDR requirements. This involves creating an approved supplier list and conducting regular audits. A centralized repository for supplier information can streamline this process.

6. Conduct a Clinical Evaluation

Manufacturers must conduct clinical evaluations to demonstrate conformity with safety and performance requirements. This involves collecting and analyzing clinical data from relevant literature and clinical investigations.

7. Assign a European-Authorized Representative (if Applicable)

Non-EEA manufacturers must appoint an authorized representative within the EEA to handle regulatory compliance, complaints, and technical documentation.

8. Obtain Certification by a Notified Body

Notified Bodies are independent organizations that assess product conformity with MDR. They audit the manufacturer’s QMS and technical documentation. A list of valid Notified Bodies can be found in the NANDO system.

9. Prepare a Declaration of Conformity

Manufacturers must prepare a Declaration of Conformity, confirming that their medical device meets MDR requirements.

10. Register Your Device Under a Unique Device Identifier

Assign a unique device identifier (UDI) to facilitate device traceability. The UDI is stored in the European Database on Medical Devices (EUDAMED).

11. Affix a CE Marking to the Medical Device

Once certified, manufacturers can affix the CE marking to their medical devices. The CE marking must be visible, legible, and durable.

12. Maintain a Post-Market Surveillance System

Manufacturers must have a post-market surveillance system to monitor device safety and effectiveness. This involves collecting data on complaints, adverse events, and non-conformances, and conducting regular audits.

Ready to Achieve CE Marking for Your Medical Device?

Conclusion

Getting a CE marking for medical devices is a comprehensive process that requires meticulous planning and execution. By following the steps outlined in this guide, manufacturers can streamline compliance and ensure their devices meet the stringent requirements of the MDR.

For more detailed information, manufacturers should consult the MDR and consider engaging with regulatory consulting firms to navigate the complexities of the CE marking process for medical devices.

Get Your CE Mark for Medical Devices with Operon Strategist

At Operon Strategist, we offer comprehensive support to guide you through the CE marking process. Our services include:

- Product Classification Assistance: Determine the correct classification for your medical device.

- Standards and Testing Requirements: Verify applicable standards and testing requirements.

- Technical File Compilation: Compile or review your Technical File or Design Dossier.

- Marketing Material Review: Ensure your labeling and user manuals meet compliance standards.

- Essential Requirements Compliance: Verify adherence to all Essential Requirements.

- Clinical Evaluation Report Preparation: Prepare a Clinical Evaluation Report based on your clinical data.

- Quality System Implementation: Implement, modify, and maintain a quality system (ISO 13485) to meet European and international standards.

- Authorized Representative Services: Provide European representation as required.

- Risk Management: Conduct risk assessments and management in line with ISO 14971.

- Post-Market Surveillance: Develop vigilance and post-market surveillance procedures.

Contact us today to learn how Operon Strategist can help you achieve CE marking for your medical device and successfully enter the European market.