CDSCO Manufacturing License for Disposable Syringe

Manufacturers need to have a CDSCO manufacturing license for disposable syringe manufacturing as a regulatory requirement.

Obtaining a CDSCO manufacturing license indicates that the manufacturer has been thoroughly evaluated and has met the required standards, ensuring the production of safe, effective, and high-quality disposable syringes. Adhering to these regulatory requirements is crucial not only for legal compliance but also to guarantee the safety and efficacy of medical devices, thereby protecting the health of consumers and patients who use these products.

Growing Demand for Disposable Syringes

The growing demand for medical facilities is set to enhance this sector. Disposable syringes are widely used by healthcare professionals to administer medications via intravenous or intramuscular routes for infection treatment and by research and development teams. Made from plastic, disposable needles are utilized in both clinical and veterinary settings. Their availability in sterile, ready-to-use forms and cost-effectiveness have led to a rapid replacement of traditional glass needles.

Many manufacturers face challenges initiating the process; while they are eager to start their projects, they often struggle due to a lack of knowledge.

Looking For Consultants?

Let’s have a word about your project

The creation of a Disposable syringe requires exceptional infusion shaping machines and extraordinary molds.

We assist in manufacturing plant layout design, regulatory aspects, clean room design, process validation, and so on. As per the data available market for medical devices will increase from 2020 to 2025. Some companies have presented a ferromagnetic infusion-forming machine for this reason. The crude material required is polypropylene. It is taken care of in the infusion forming machine and shaped in a chilled condition to improve lucidity. The formed needles are then gathered with the needle in a programmed get-together machine. The entire get-together is then sanitized in a sanitization plant utilizing ethylene oxide. The finished needle is then rankling pressed in a programmed pressing machine.

Disposable Syringe Manufacturing Process

A disposable syringe is a fundamental device consisting of a plunger that fits securely inside a cylindrical chamber known as the barrel. The plunger can be pulled and pushed within the chamber, allowing the syringe to draw in and expel liquid or gas through an opening at the front.

The open end of the barrel may be equipped with a hypodermic needle, nozzle, or tubing to facilitate the flow of substances in and out of the barrel. Disposable syringes are commonly used in medical settings for administering injections, delivering intravenous treatments, applying substances like adhesives or lubricants, and measuring or drawing liquids.

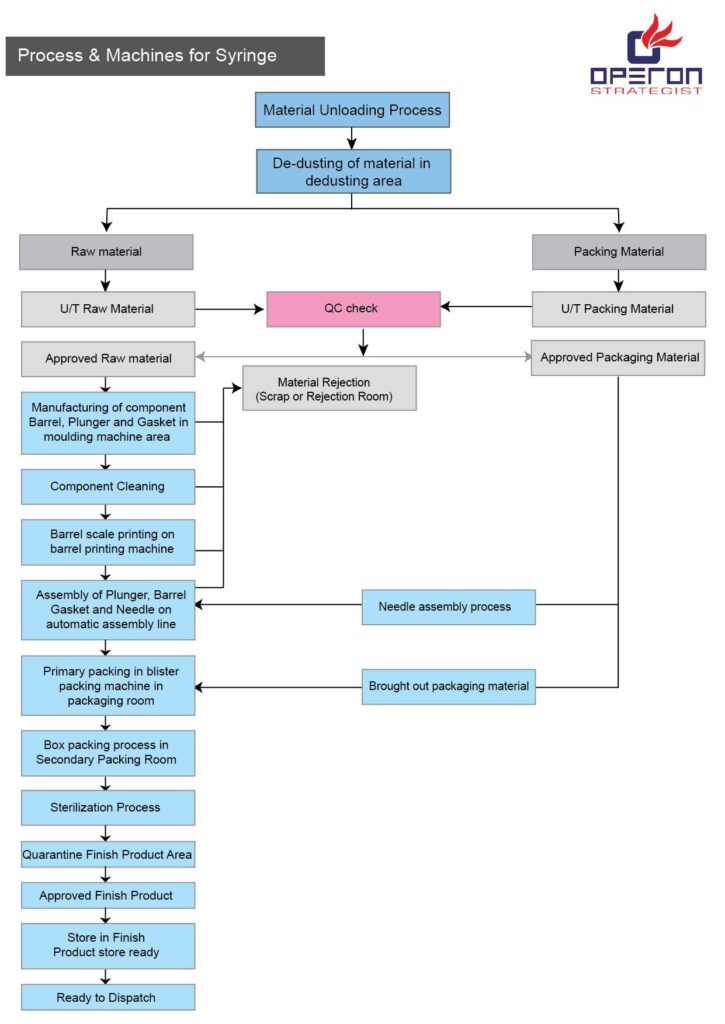

The manufacturing process begins with de-dusting the raw materials and packaging materials, ensuring that any unwanted debris is removed. The steps in the manufacturing process are detailed in the accompanying flowchart. Quality control is a critical aspect of production, as these devices come into direct contact with the human body. Both raw and packaging materials undergo in-process quality control testing. Only approved materials are used in production, while rejected materials are sent to the designated rejection area.

Initially, the entire Disposable syringe creation line is fabricated with the utilization of Polypropylene. You need to settle on a choice about which sort of sizes you need to make. The typical standard charges are 1ml, 2ml, 5ml, and 10ml. due to well-being mindfulness and well-being awareness, you can get a ton of benefits on Disposable syringes and assembling of needle business.

Effectively most needle creation line was made of glasses. As a result of their openness in sterilized condition, arrangement to use, and cost sufficiency, disposable syringes are briskly displacing the glass needles. The movement of AIDS and related deadly infirmities worldwide has included not using the reuse of needles and the interest in superfluous needles has extended unfathomably.

Get Quotation for Disposable Syringe Manufacturing Plant Setup and Regulatory Consultancy

Manufacturing Machinery for Disposable Syringe

Machinery used

- Injection molding machine

- Barrel Printing machine

- Syringe Assembly machine.

- Syringe Feeding machine.

- Blister Packaging machine,

- Ribbon Packaging machine

Other Auxiliary machinery

- Dryer

- Mixer

- Chiller

- Scrap grinding machine.

- QC equipment’s etc.

The disposable syringe has wide market potential. The deep-rooted glass needles are exceptionally quick getting old.

Read More: Disposable Syringe Manufacturing Process and Machineries

Manufacturing Raw Materials

Raw materials which is used in preparing disposable syringes are listed below:

There are generally two types of raw materials, required to manufacture syringes. The first one is polypropylene and the other is elastomer (Rubber) other than this which is used in preparing disposable syringes are listed below:

| S. No | Name of the raw Material | ||

| 1 | Needle (SS) | ||

| 2. | Packing Material (Corrugated Boxes, Printing Roll, etc.) | ||

| 3. | Printing Ink | ||

| 4. | Silicon | ||

| 5. | EO Gas |

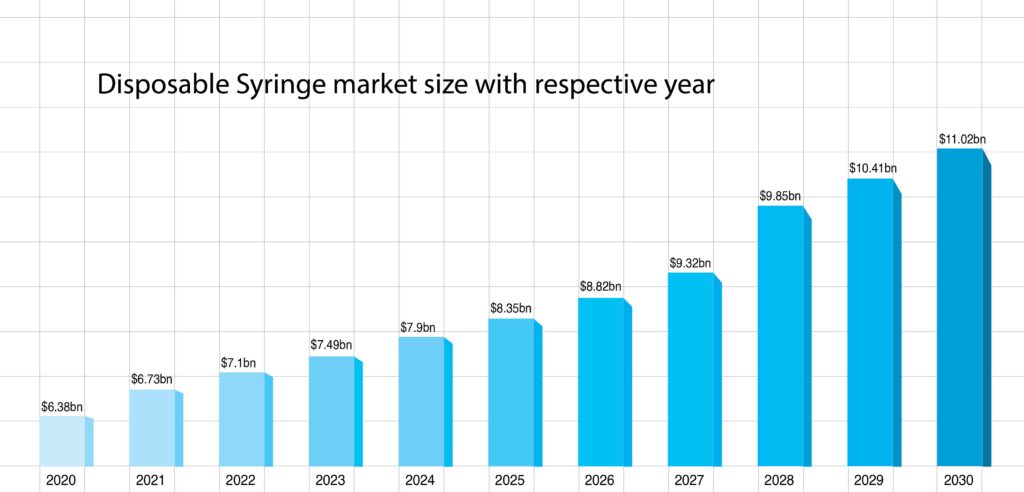

Disposable syringe market size as per data available on various portals graphical representation of disposable syringe market size/year by year representation of disposable syringe market size.

The rapid growth of the disposable syringe industry is driven by the global demand for vaccines, government funding, and advancements in medical technology. Research indicates that the market will continue to expand due to the increasing adoption of self-injection devices, innovations in syringe technology, and supportive government initiatives.

Disposable syringes are increasingly replacing traditional glass syringes due to their accessibility, sterilized condition, ready-to-use nature, and cost-effectiveness. Additionally, the global fight against diseases like AIDS has highlighted the risks associated with needle reuse, further boosting the demand for disposable syringes.

Typically made from polypropylene through injection molding, disposable syringes come in various sizes, including 1 ml, 2 ml, 5 ml, 10 ml, and 50 ml. The manufacturing setup, including the number of injection molding machines and mold cavities, depends on the design and annual production requirements.

Role of Operon Strategist

Operon Strategist plays a pivotal role in the disposable syringe manufacturing industry. By leveraging their expertise in regulatory affairs and quality management, Operon Strategist ensures that disposable syringe manufacturers can focus on innovation and production while maintaining compliance with global regulatory standards. This holistic approach not only facilitates market access but also enhances the safety and efficacy of disposable syringes, ultimately benefiting patients and healthcare providers.