Manufacturers need to have a CDSCO manufacturing license for disposable syringe manufacturing as a regulatory requirement.

Obtaining a CDSCO manufacturing license signifies that the manufacturer has undergone scrutiny and met the specified standards, ensuring the production of disposable syringes that are safe, effective, and of high quality. Compliance with these regulatory requirements is essential not only for legal reasons but also to ensure the safety and efficacy of the medical devices being produced, safeguarding the health of consumers and patients who will ultimately use these products.

Growing Demand for Disposable Syringes

Rising demand for medical facilities will give a boost to this sector. Disposable Syringe is being utilized by specialists to infuse medicines through intravenous or intramuscular ways for the treatment of infections and likewise by research and advancement faculty. Expendable needles are made of plastic material and are utilized in the field of clinical and veterinary science. Due to their accessibility in sanitized condition, prepared to utilize, and cost viability, expendable needles are quickly supplanting the well-established glass needles.

Many manufacturers struggle with the initiation process, they do want to start the project but they can’t, due to a lack of knowledge.

Looking For Consultants?

Let’s have a word about your project

The creation of a Disposable syringe requires exceptional infusion shaping machines and extraordinary molds.

We assist in manufacturing plant layout design, regulatory aspects, clean room design, process validation, and so on. As per the data available market for medical devices will increase from 2020 to 2025. Some companies have presented a ferromagnetic infusion-forming machine for this reason. The crude material required is polypropylene. It is taken care of in the infusion forming machine and shaped in a chilled condition to improve lucidity. The formed needles are then gathered with the needle in a programmed get-together machine. The entire get-together is then sanitized in a sanitization plant utilizing ethylene oxide. The finished needle is then rankling pressed in a programmed pressing machine.

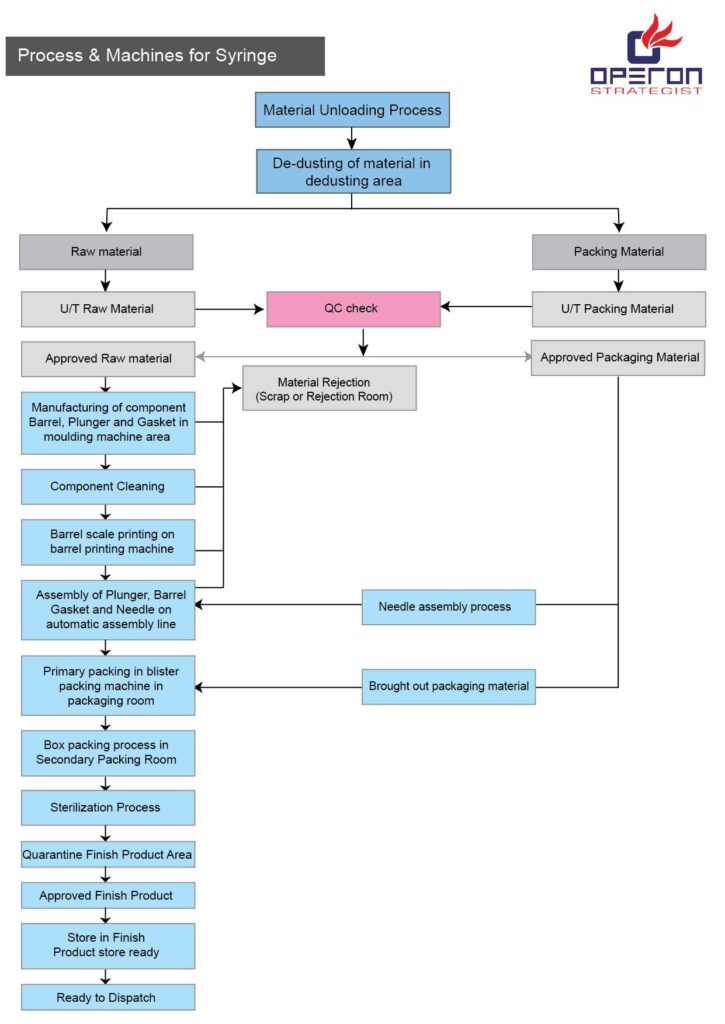

Disposable Syringe Manufacturing Process

A Disposable syringe is a fundamental reacting siphon including an unclogged one that fits solidly inside a round and empty chamber called a barrel. For needle production unclogged can be legitimately pulled and pushed along inside the chamber, empowering the needle to take in and expel liquid or gas through a delivery opening at the front (open) part of the deal.

The open portion of the deal may be fitted with a hypodermic needle, a spout, or tubing to organize the stream into and out of the barrel. Disposable syringes are as frequently as conceivable used in clinical drugs to control implantations, pervade intravenous treatment into the circulatory framework, apply blends, for instance, glue or oil, and draw/measure liquids.

In the process of manufacturing the first step should be de-dusting of raw material & packing material, if any unwanted material stuck with these materials will be removed in this process. The steps followed in the manufacturing process are explained in the above flow chart. Quality Control check is the most important step in the manufacturing process as this will directly come in contact with the human body. The raw material and packaging material will go through in-process quality control testing. Approved material is used for production purposes and rejected material is sent to the rejection room.

Get Quotation for Disposable Syringe Manufacturing Plant Setup and Regulatory Consultancy

Initially, the entire Disposable syringe creation line is fabricated with the utilization of Polypropylene. You need to settle on a choice about which sort of sizes you need to make. The typical standard charges are 1ml, 2ml, 5ml, and 10ml. due to well-being mindfulness and well-being awareness, you can get a ton of benefits on Disposable syringes and assembling of needle business.

Effectively most needle creation line was made of glasses. As a result of their openness in sterilized condition, arrangement to use, and cost sufficiency, disposable syringes are briskly displacing the glass needles. The movement of AIDS and related deadly infirmities worldwide has included not using the reuse of needles and the interest in superfluous needles has extended unfathomably.

Manufacturing Machinery for Disposable Syringe

Machinery used

- Injection molding machine

- Barrel Printing machine

- Syringe Assembly machine.

- Syringe Feeding machine.

- Blister Packaging machine,

- Ribbon Packaging machine

Other Auxiliary machinery

- Dryer

- Mixer

- Chiller

- Scrap grinding machine.

- QC equipment’s etc.

The disposable syringe has wide market potential. The deep-rooted glass needles are exceptionally quick getting old.

Read More: Disposable Syringe Manufacturing Process and Machineries

Manufacturing Raw Materials:

Raw materials which is used in preparing disposable syringes are listed below:

There are generally two types of raw materials, required to manufacture syringes. The first one is polypropylene and the other is elastomer (Rubber) other than this which is used in preparing disposable syringes are listed below:

| S. No | Name of the raw Material | ||

| 1 | Needle (SS) | ||

| 2. | Packing Material (Corrugated Boxes, Printing Roll, etc.) | ||

| 3. | Printing Ink | ||

| 4. | Silicon | ||

| 5. | EO Gas |

Land requirements are generally decided according to your business size, major area used for warehouses and production, and occupancy requirement to set up a plant

- Skilled workers/Unskilled worker

- Supervisors

- Security

- Account assistant

- Marketing Executive

- QA head, QC head, Production head

- Executive officers for each department.

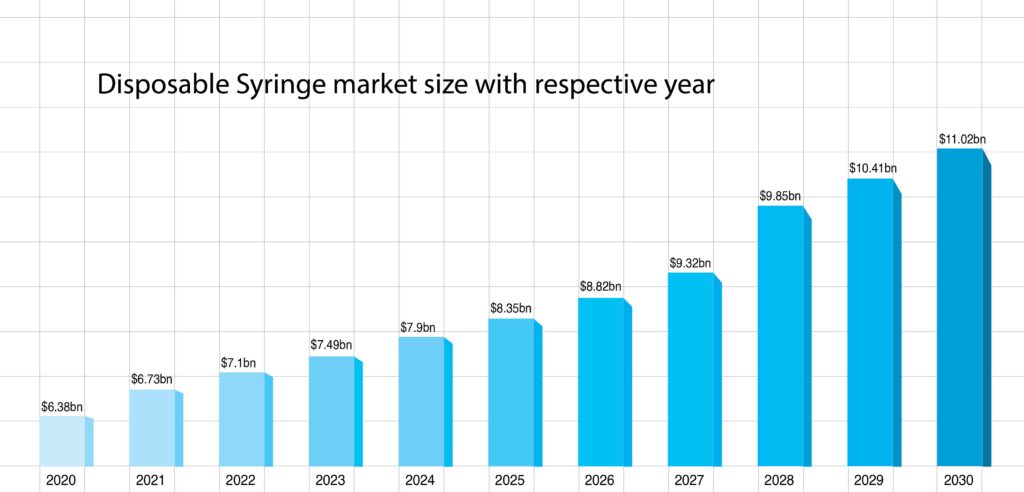

Disposable syringe market size as per data available on various portals graphical representation of disposable syringe market size/year by year representation of disposable syringe market size.

The rapid growth in this industry can be seen as there is a demand for vaccines all over the world. Moreover, the government is providing funds. As per the research, there will be growth in this industry due to the growing demand for self-injection devices, advancements in needle and syringe technology, and government initiatives.

Because of their accessibility, sanitized condition, preparedness to utilize, and cost adequacy, disposable syringes are quickly supplanting the well-established glass needles. Additionally, the ghastliness of Helps worldwide has nearly coincided with the reuse of needles, and the request for dispensable needles has expanded marvelously. Disposable syringes are generally infusion-shaped and made of polypropylene. Needles are accessible in sizes of 1 ml, 2 ml, 5 ml, 10 ml, and 50 ml in an assortment of plans and comprise a few segments of development. The number and size of infusion shaping machines required depend on needle development, number of shape cavities, and yearly creation. Our work in the field of medical device regulatory consulting provides support on a one-on-one basis and guides our clients for steady growth.

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/