What Are Implantable Medical Devices?

Implantable medical devices are incredible little gadgets that work quietly inside your body, helping keep things running smoothly. These devices are designed to perform specific tasks, like supporting your heart or keeping an eye on your blood pressure, all while you go about your day without even noticing them. Some of these devices, known as active implantable medical devices (AIMDs), need a power source to keep them going, but their job is crucial for long-term health, making sure your body stays balanced and healthy, almost like having a little helper inside.

How Are Implantable Medical Devices Changing the Healthcare Game?

- Monitoring: Devices like implantable blood pressure sensors keep track of your health in real-time, so you don’t have to worry about checking your condition manually.

- Supporting: Ventricular Assist Devices (VADs) help weak heart muscles keep blood circulating, taking some of the strain off your heart.

- Treatment: From deep brain stimulators for managing Parkinson’s disease to cochlear implants that restore hearing, implantable devices are offering hope for those in need of treatment.

The Process Behind Making Implantable Medical Devices

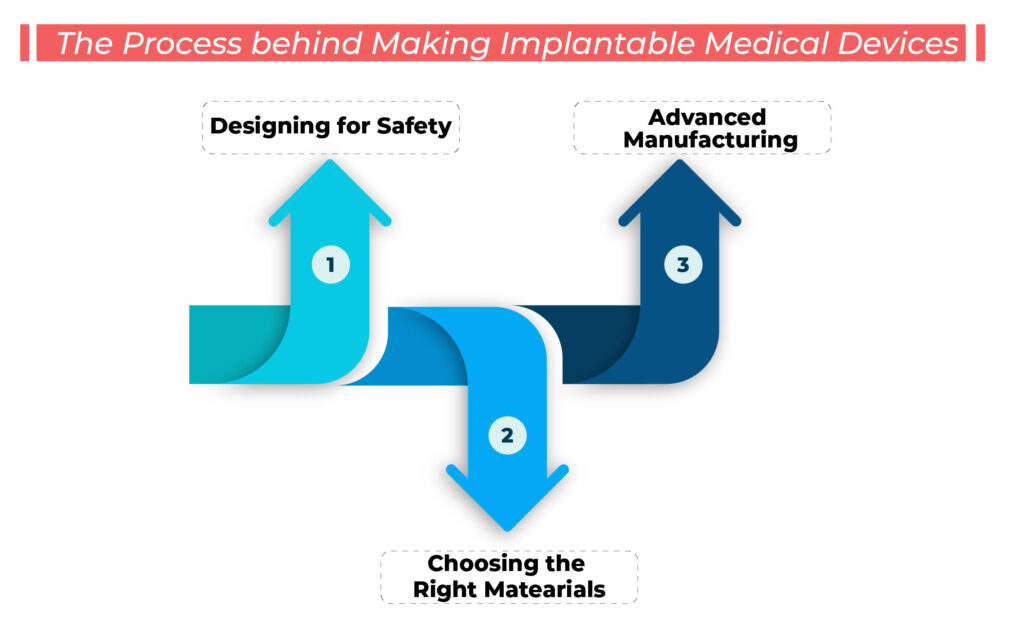

Creating these life-saving devices is a delicate process that combines precision and care:

- Designing for Safety: These devices must stay within specific limits, like maintaining body temperature and insulating electrical parts to avoid harm.

- Choosing the Right Materials: Manufacturers select only biocompatible materials to ensure that the body can safely accept and tolerate the device.

- Advanced Manufacturing: Cutting-edge technology and strict quality control make sure the devices are safe, reliable, and ready for long-term use inside the body.

Navigating the Regulatory Path for Implantable Medical Devices

Getting these devices to market isn’t easy—each country has its own rules:

Know More About Implantable Medical Devices In Detail!

How Operon Strategist Helps Manufacturers

This is where Operon Strategist makes a difference. They guide manufacturers through the complex process of designing, developing, and certifying their implantable devices. From choosing the right materials to navigating tough regulations like ISO 13485, US FDA, CE, and CDSCO, they ensure everything meets the highest safety standards and that the device gets to market as quickly and smoothly as possible.

The Future of Healing Technology

Implantable medical devices are changing the way we approach health and treatment. These aren’t just pieces of technology—they’re improving and saving lives. With the right support and guidance, manufacturers can bring these innovative devices to the people who need them, making healthcare safer and more effective for everyone. Technology is no longer just something that supports our lives; it’s helping heal from the inside out.