Overview of ISO 13485 Internal Audit

ISO 13485 internal audit is a critical component of a Quality Management System (QMS). It effectively identifies and addresses any potential risks or non-conformities. The internal audit checklist will help the organization ensure that its processes and procedures comply with the requirements of ISO 13485.

If you are new to the field of medical devices and wondering what ISO 13485 is, you can check our service page ISO 13485 Certification Consultant to get some idea about it.

And if you want to learn more about the internal audit checklist, continue reading this blog.

Looking for ISO 13485 Internal Audit Checklist?

Lets have a word about your project

Why Is an Internal Audit Required?

ISO 13485 is an international standard for quality management systems of medical devices. One of the clauses (8.2.4) in it requires an organization to conduct internal audits at timely intervals to ensure the effectiveness of the QMS.

An effective internal audit will help organizations maintain a high level of quality control over their products and services, while also ensuring compliance with international regulations. These internal audits will also prepare the organization for further external audits and third-party verifications.

Operon strategist is a leading medical device regulatory consultant with professionals having an in-depth knowledge of ISO 13485 and other regulatory certificates.

ISO 13485 Internal Audit Requirements

Any medical device manufacturing company is required to carry out the ISO 13485 internal audits regularly to ensure the quality and safety of the device. The internal audit section in 13485 mentions that the organization performs an internal audit program, solves problems identified during the audit, and verifies if problems are resolved.

We have broken down the requirements for better understanding:

- Design the Audit Program

An organization’s internal audit program must include documentation and all implementation components. This step must clearly define what is to be audited, who is responsible for the audit, and when the audit should be done.

- Plan and Execute

Internal audits are typically conducted twice a year or annually. This depends totally on the organization and management.

After deciding when the audit is to be conducted, a concrete plan is required to ensure the availability of all the stakeholders on the scheduled date and time.

An audit may consist of reviewing past records, interviewing employees, or observing the process itself.

- Report of Audit

Post-audit, the auditor will meet with the stakeholders to discuss the findings and also provide any potential improvements that could be made. The auditor should provide a written report summarizing the audit results and any proposed corrective action.

- Taking Actions

If in the audit any non-conformities or issues are identified, it is crucial to take action to resolve them and ensure that they are not repeated in the future. Corrective action and Preventive action (CAPA) are an integral part of the audit process.

- Follow-up and Verification

Follow-up is an essential part of a successful audit. It is critical to ensure that the problems found during the audit were addressed and respective action is taken to resolve them.

Scope of Your Internal Audits

Internal audits can be taken as an opportunity to streamline the process for overall organizational improvement. Determining the scope will ensure that audits are comprehensive and not just a mundane mandatory activity.

Depending on the complexity of the medical device, the scope of the internal audits may vary. A medical device consultancy like us might be able to guide you in defining the right plan for your ISO 13485 internal audits. Reach out to us for more information Contact Us

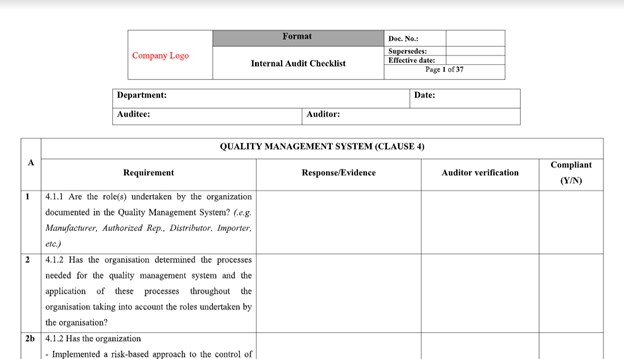

How to Create ISO 13485 Internal Audit Checklist?

An ISO 13485 internal audit checklist is a technical document which verifies all the clauses in ISO 13485. The checklist may be modified based on organizational requirements, and manufacturing processes. It will also differ department-wise as in QA, Production, and Sales will have different checklists. A general ISO 13485 internal audit checklist will look something like this:

The checklist should ensure all clauses are verified and the QMS complies with ISO 13485. Taking the services of a medical device consulting firm can be a wise move for a small business or someone new to the field.

Operon strategist is a team of medical device experts who can guide you in every step of internal audit to smoothen the process for you.

How to Conduct Internal Audits Effectively?

An important aspect of internal audit is that the process owner cannot audit their own processes as it will not be credible. For an effective internal audit organization must ensure the following:

- Employees who will be auditing are well-trained on what and how to audit. If it is a small organization, then consultants might be involved and again they must be trained in the audit process by the company.

- The auditor must be unbiased and provide honest feedback. Auditor must be from a different department to ensure this.

- Have a dedicated team for your internal audits. This will ensure a smooth audit process.

ISO 13485 Internal Audit is an important part of the quality management system. It is like a tool that will help the organization to verify that the system is compliant with all applicable standards and regulations. Internal audits can be conducted by Quality managers/auditors within a company or with the help of a consultant or medical expert.

Internal audits can prevent major losses in the future which can be caused due to a faulty system. It helps in identifying areas of risk and potential non-conformities, which can then be addressed by implementing corrective actions.

As an ISO 13485 medical device consultant, we identify the specific regulatory requirement for the product such as MDR, and FDA 510(k) during the implementation. We also, provide services for MDSAP regulation for manufacturers. This helps manufacturers in the further process of CE mark medical devices or FDA 510 (k) clearance.