Medical Device Design & Development Consultant

A medical device design and development consultant provides specialized expertise and guidance to companies involved in creating and refining medical devices. These consultants support various phases of the device development lifecycle, offering insights, strategies, and technical assistance to ensure the successful design, development, and eventual market launch of medical devices. Operon Strategist’s guidance is instrumental in ensuring that devices meet regulatory standards, address user needs, and adhere to industry best practices.

What is Medical Device Design?

The development of a medical device entails the creation of a specialized device intended for medical purposes. Our team of medical device designers emphasizes adherence to current regulations and the adoption of industry best practices. Generally, the medical device design process involves several crucial steps.

Understanding Medical Device Design and Development

Medical Device Design and Development plays a vital role in making the medical device that meets quality expectations at par and may not lead to customer complaints and failure in the market. The routes that cause most of the customer complaints, recalls, and device failures are poor medical device design and development activity. Any product failure is a major non-compliance & may result in adverse events affecting users.

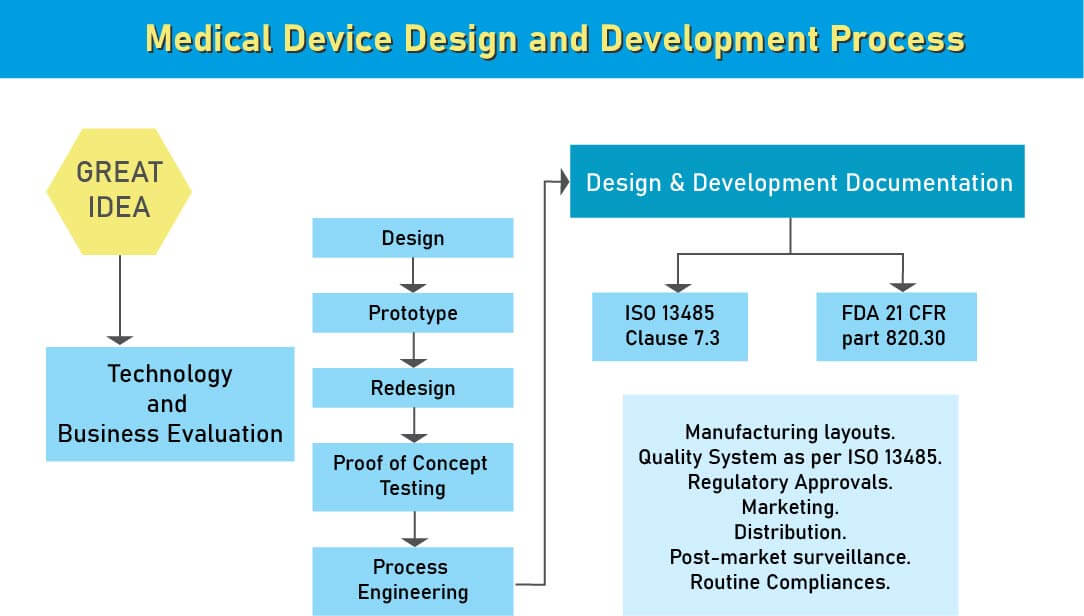

The Medical Device Design and Development Process Guide

In the design and development phase of medical device creation, our consultancy supports various industries in Saudi Arabia to ensure regulatory compliance. Following the analysis of a new medical device, the subsequent step involves its design. This phase is paramount, as a flawed design could render the device ineffective or hazardous. Implementation of a design control process system is essential during this stage to ensure accuracy and alignment with customer requirements. Design controls involve straightforward and systematic steps to guarantee that the developed product fulfills the intended objectives and meets customer expectations.

Looking For Regulatory Consultants in Saudi Arabia?

Let’s have a word about your next project!

- Medical device development uses a ton of comparative parts in a large number of various medical devices. A solid definition extricated by dissecting the market needs. When you’re finished with the product’s definition and thought, you have to consider systems like the FDA has characterized and licensed innovation rights. Medical device classification depends on the hazard related to the utilization and upheld by law. So as to get into the market, the medical devices need to go through certain administrative compliances, subject to both provincial and worldwide guidelines. Medical device measures are useful and upheld by law in indicating and assessing the prerequisite for structure and execution parameters for biomedical materials, apparatuses, and gear. These medical device standards permit establishments in the medical device field, for example, product manufacturers, research centers, and others to review and survey such hardware and devices to guarantee standard quality and ease of use.

- The International Organization for Standardization likewise has details for medical device principles. ISO 13485 is broadly utilized guidelines all over the world for medical device quality administration. Other than these worldwide models, there are certain gauges that are area-explicit and every one of them is embraced by universal norms with little adjustment and constraint.

- Medical device manufacturers need to pursue Design Control rules since administrative bodies like the FDA, the European Commission, and others need to guarantee that the medical devices are right for potential clients before makers begin to advertise the devices. The beginning stage from which Design Control starts is Design Input advancement and endorsement, which comprises device design and manufacturing procedures to be completed in the generation stage. Design control is a comprehensive methodology and doesn’t end with moving the design to the generation stage when the plan is settled. It additionally affects manufacturing procedures as indicated by the adjustments in the design stage or even after creation input. It is a progressing procedure to build up a product that is usable for a client and in this way for the improved product, it considers progressive changes from utilization design just as breaking down failed items.

Why is Medical Device Design Important?

When it comes to medical device development, the absence of comprehensive design and development documentation covering all the stages of the design of a product is not just a setback, it can be a permanent barrier to getting to market.

For those serious about developing a medical device that can make it through to launch, giving early consideration to the overall governance of the design elements of your project and how it will be recorded is essential. This includes creating a functioning system of design control before you begin that will guide, manage, and document the progress of your project from ideation to the start of development and beyond.

What Do You Mean by Design Control Medical Device?

Design control, which is commanded by the FDA, addresses a formalized way to deal with the advancement of Class II and Class III medical devices. This process incorporates many layers of required documentation that show the FDA precisely the way in which you have accommodated the well-being and viability of your new device. So it is important for medical device design and development companies to classify their product so that required design control can be done.

What is Product Development in Medical Devices?

Medical product development depicts the total course of fostering a medical device that beginnings with seeing a chance for a medical device to finally sell the last tried and certified item. This process incorporates many stages, including opportunity identification, market examination, idea generation and determination, product plan, device designing, commercialization, and post-market surveillance.

How to Design and Develop a Medical Device?

It takes a significant amount of effort to deliver the right healthcare solution that meets customer demands. A right healthcare solution demands everybody to stay on the same page, with a strong scope definition from the end user’s need, collaborative efforts across the team, adherence to specifications and requirements extracted from product definition, simultaneously mitigating risks and sticking to the best possible quality.

Medical Device Design Services & Product Development Process?

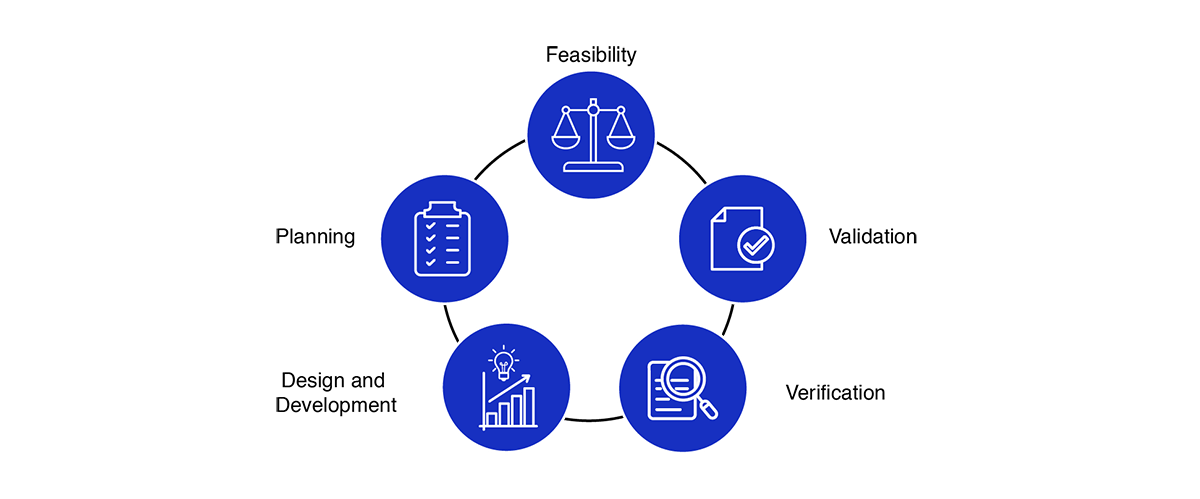

- Feasibility

- Planning

- Design and development

- Verification

- Validation

Medical device design services and development processes encourage an early focus on clear problem definition and de-risking a wide variety of potential solutions. By later phases, the funnel of medical device design options narrows significantly, converging on a final product that has been thoroughly shown to meet customer needs and is ready for distribution.

The Medical Device Design and Development Services Includes :

Combination Product - Drug - Device

Each manufacturer of Drug Device combination products (e.g. Drug, device combination products like prefilled syringes, applicators of the tropical products) shall have adequate design and development activity done so as to prove the adequacy of the safety and efficacy of the product. The medical device design and development activity is the systematic methodology, which establishes the proper medical device design and development.

Medical Device Design Control

After conceptualizing a new medical device, the next step in its product advancement is the design. This is the most important stage in the advancement of a medical device since a defective plan may prompt it to be inadequate or dangerous (that is, not affirmed or cleared by the administrative organization). At the medical device design stage, an outline control process should be started and actualized as a feature of the quality system requirement.

For Expert Consulting Services for Medical Device Design and Development

Our Role in Device Design Control:

We help you to meet your regulatory goals, and our associations with the leading industry players help us to build a good network. As medical device design consultants we validate the tools, provide guidance and training to medical device manufacturers in Saudi Arabia to implement Qualitative QSM, and work with your team to get regulatory compliance. You can rely on us for cost-effective, error-free, and timely services.