An Overview of an Effective CAPA System:

The Corrective and Preventive Action (CAPA) system is a cornerstone of any effective quality management system (QMS) in the MedTech industry. Whether you’re aiming to comply with 21 CFR Part 820.100 or ISO 13485:2016, a well-structured CAPA process is essential for ensuring product quality, regulatory compliance, and most importantly, patient safety.

Unfortunately, ineffective CAPA systems are a recurring cause of FDA Form 483 observations and ISO audit nonconformities. Many companies still struggle with implementing a system that is both compliant and truly effective.

In this article, we’ll walk you through the 5 key elements of an effective CAPA system and how to overcome the most common challenges. We’ll also share how partnering with a regulatory expert, such as Operon Strategist, can make all the difference.

Looking For a Medical Device Regulatory Consultant?

Let’s have a word about your next project

What is a CAPA System?

A CAPA system is a structured process that identifies, investigates, and corrects or prevents quality issues within a medical device organization. The goal is not just to treat surface-level symptoms but to dig deep, identify root causes, and prevent recurrence.

A robust CAPA system involves:

- Detecting issues from audits, complaints, returns, or internal reports

- Analyzing root causes

- Taking corrective or preventive actions

- Verifying effectiveness

- Documenting every step

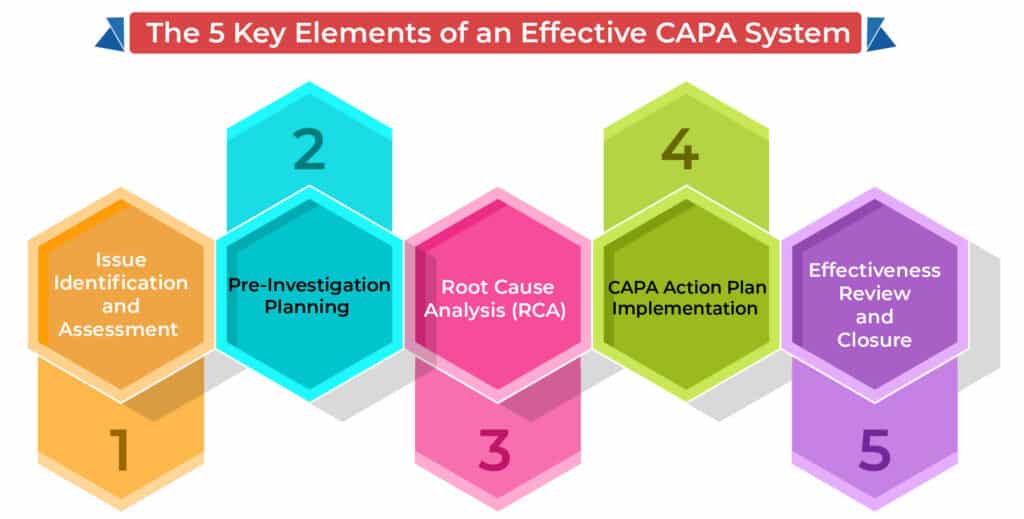

The 5 Key Elements of an Effective CAPA System

Issue Identification and Assessment

Every CAPA starts by recognizing a potential issue. This may originate from:

- Internal/external audits

- Non-conformance reports

- Product failures

- Customer complaints

Once identified, the issue must be formally documented and evaluated. A Quality Review Board (QRB) or Material Review Board (MRB) typically determines whether a full CAPA is required or if the issue can be resolved through other channels.

Tip: Not every issue should trigger a CAPA. Focus on systemic issues with potential impact on safety or compliance.

Pre-Investigation Planning

Once a CAPA is initiated, the scope must be clearly defined. Assign a unique tracking number, create a cross-functional team, and outline investigation goals. Key stakeholders may include representatives from:

- Quality Assurance

- R&D

- Regulatory Affairs

- Production/Engineering

Early in the process, the team must determine whether immediate containment actions—such as halting production or issuing recalls—are necessary.

Root Cause Analysis (RCA)

Effective CAPA systems rely heavily on in-depth RCA. Without identifying the true root cause, you risk repeating the same issue.

Common RCA tools include:

- 5 Whys Method

- Fishbone (Ishikawa) Diagram

- Fault Tree Analysis

- Pareto Analysis

Documentation is critical at this stage. Include all supporting evidence, testing data, and investigation notes.

Common Pitfall: Jumping to conclusions or skipping RCA methods leads to temporary fixes and future non-conformities.

CAPA Action Plan Implementation

With the root cause identified, it’s time to develop and execute your CAPA action plan, which may include:

- Corrective Actions (fixing existing problems): e.g., re-training staff, redesigning a process, updating SOPs

- Preventive Actions (avoiding future issues): e.g., risk analysis, statistical trend reviews, supplier evaluations

The plan should include:

- Assigned responsibilities

- Deadlines

- Resources required

- Methods of effectiveness verification

Effectiveness Review and Closure

Before closing a CAPA, conduct Verification of Effectiveness (VOE). This may include:

- Trend analysis

- Follow-up audits

- Complaint tracking

- Process re-evaluations

Once verified, the CAPA can be officially closed, but continuous monitoring is key to long-term success. Ineffective CAPAs should be reopened and re-investigated as needed.

Common Challenges in CAPA Implementation

🔸 Poor Root Cause Analysis

Jumping to conclusions without structured RCA leads to ineffective corrective actions.

🔸 Overuse or Underuse of CAPA

Triggering a CAPA for every minor issue wastes time. Failing to trigger CAPAs for serious issues invites compliance trouble.

🔸 Lack of Cross-functional Involvement

Leaving CAPA ownership to the quality team alone reduces effectiveness. Involve cross-functional teams for a well-rounded approach.

Strengthen Your Capa System With Expert Guidance

Why Choose Operon Strategist for CAPA System Implementation?

At Operon Strategist, we help MedTech companies develop, implement, and optimize their CAPA systems as part of a comprehensive QMS strategy. Our team ensures:

- Full compliance with ISO 13485, FDA 21 CFR Part 820, and EU MDR

- Customized CAPA procedures aligned with your business model

- Training for your team on RCA tools and SOPs

- Seamless integration of CAPA with risk management, design control, and production processes

✅ We ensure that your CAPA system doesn’t just check boxes—it drives real quality improvements.

Ready to Strengthen Your CAPA Process?

Partner with an Operon Strategist to build a CAPA system that meets global regulatory standards and boosts product quality.

Contact us today to schedule your consultation and get expert support for CAPA implementation and QMS optimization.