Understanding 3D Printing in Intraocular Lenses Development

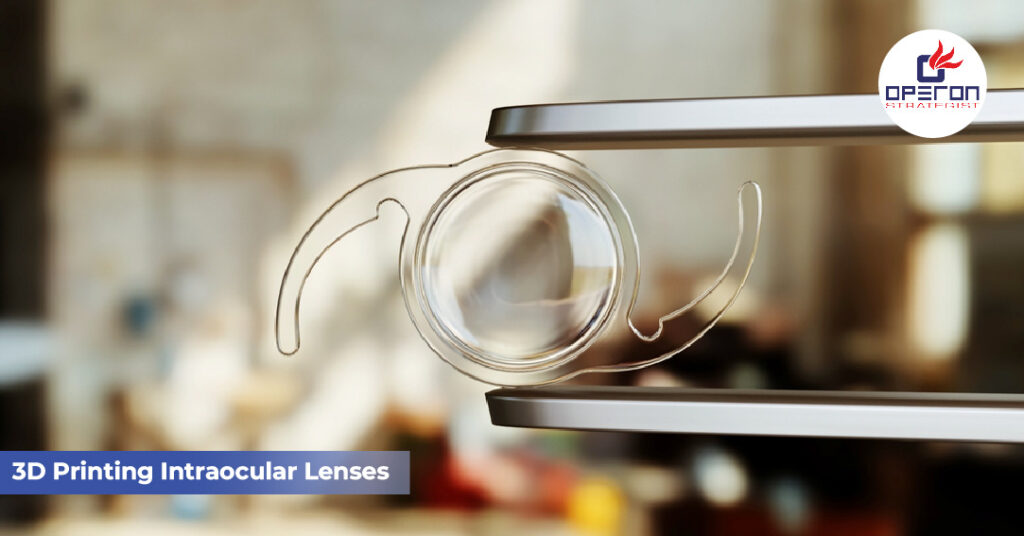

Intraocular lenses (IOLs) are vital medical devices used to restore vision after cataract surgery. Traditionally, IOLs have been manufactured using cast molding and lathe-cutting techniques, which limit customization and slow down innovation. With the emergence of 3D printing (additive manufacturing), the landscape of intraocular lens development is rapidly changing.

3D printing intraocular lenses allows manufacturers to create patient-specific designs, complex optical geometries, and rapid prototypes with unmatched precision. This technology enhances visual outcomes for patients and enables manufacturers to innovate faster while maintaining compliance with global medical device regulations.

Looking For a Medical Device Regulatory Consultant?

Let’s have a word about your next project

Opportunities of 3D Printing Intraocular Lens

1. Customization and Personalization

3D printing enables patient-specific IOL designs, offering superior refractive accuracy compared to standard lenses. Our Medical Device Design & Development Services assist manufacturers in creating these customized solutions efficiently.

2. Accelerated Prototyping and Innovation

Rapid prototyping allows testing of multifocal, trifocal, and extended depth-of-focus (EDoF) IOL designs quickly, reducing time to market. Our Rapid Prototyping Services help manufacturers bring innovative designs to production faster.

3. Advanced Optical Designs

Complex diffractive or fractal lens geometries are easier to produce using 3D printing, improving toric IOL stability and overall visual performance.

4. Sustainability and Cost Efficiency

3D printing reduces material waste and supports small-batch or local manufacturing, offering a cost-effective and sustainable solution for ophthalmic device companies.

Challenges in 3D Printing Intraocular Lens Manufacturing

1. Material Limitations

Ensuring biocompatibility and optical clarity is critical. 3D printed polymers must resist opacification and maintain long-term stability. Our Material Testing & Validation Services help manufacturers meet global standards.

2. Surface Quality

Ultra-smooth surfaces are required for optimal optical performance. Post-processing and polishing are essential to meet medical device quality standards.

3. Regulatory Compliance

IOLs are Class III medical devices, requiring strict adherence to FDA, CE MDR, CDSCO, and ISO standards. Our Regulatory Compliance Consulting Services guide manufacturers through approvals and documentation.

4. Scalability and Cost

While prototyping is faster, mass production of 3D printed IOLs remains challenging. Our Manufacturing Support Services help companies scale production efficiently.

Future Innovations in 3D Printed Intraocular Lenses

- Drug-Eluting IOLs: Lenses delivering anti-inflammatory or anti-fibrotic drugs.

- Light-Adjustable IOLs: Refractive power fine-tuned post-implantation.

- Smart IOLs: Sensor-integrated lenses or dynamic optical adjustment.

- AI-Driven Design: Using artificial intelligence to optimize lens geometry and patient-specific customization.

These advancements position 3D printed intraocular lenses as the future of cataract surgery and ophthalmic innovation.

Global Market Outlook

The demand for premium IOLs is rising, particularly in India, Europe, and the USA. Integrating 3D printing in intraocular lens manufacturing reduces costs, supports regional production, and increases accessibility to advanced IOL designs.

Looking For a Medical Device Regulatory Consultant?

How Operon Strategist Empowers Manufacturers?

At Operon Strategist, we partner with medical device innovators to turn groundbreaking ideas into regulatory-compliant, market-ready solutions. Our team combines technical expertise, regulatory knowledge, and industry experience to guide companies through every stage of 3D printed IOL development, ensuring efficiency, safety, and global compliance.

Here’s how we help:

- Product and Process technology support

- Support on getting the product manufacturing technology and experts.

- Technology transfers

- Design and Setting up Manufacturing facility

- Create the manufacturing setup as per regulatory compliance and global standards of US EU and CDSCO.

- Regulatory Compliance Guidance

- Navigate FDA, CE MDR, CDSCO, and ISO regulations efficiently.

- Prepare documentation, risk assessments, and validation plans.

- Material Testing & Quality Assurance

- Ensure biocompatibility, optical clarity, and surface precision meet global standards.

- Market Strategy & Global Readiness

- Provide insights for launching IOL innovations in India, Europe, USA, and beyond.

Partnering with Operon Strategist enables manufacturers of 3D printed intraocular lenses to innovate faster, achieve compliance, and deliver life-changing solutions to patients worldwide.