Manufacturing Plant Facility Layout Design

Manufacturing Plant Layout Design for Medical Devices

For any manufacturing plant set up, manufacturing plant layout designing is a starting stage. For the industry like medical device and packaging, plant layout design must be compliant with specific rule set by the respective regulatory authority. Our team provide guidance to the manufacturers on how to get compliant with regulations for plant layout designs.

Medical Device Manufacturing plant must be compliant with the rules given by respective regulatory bodies like USFDA, CDSCO, SFDA etc.

Manufacturers of medical devices like orthopedic implants, disposables and other medical devices, primary packing material & various pharma products need to have proper design for their manufacturing unit to meet cGMP requirements& other regulatory requirements.

Looking for Consultant?

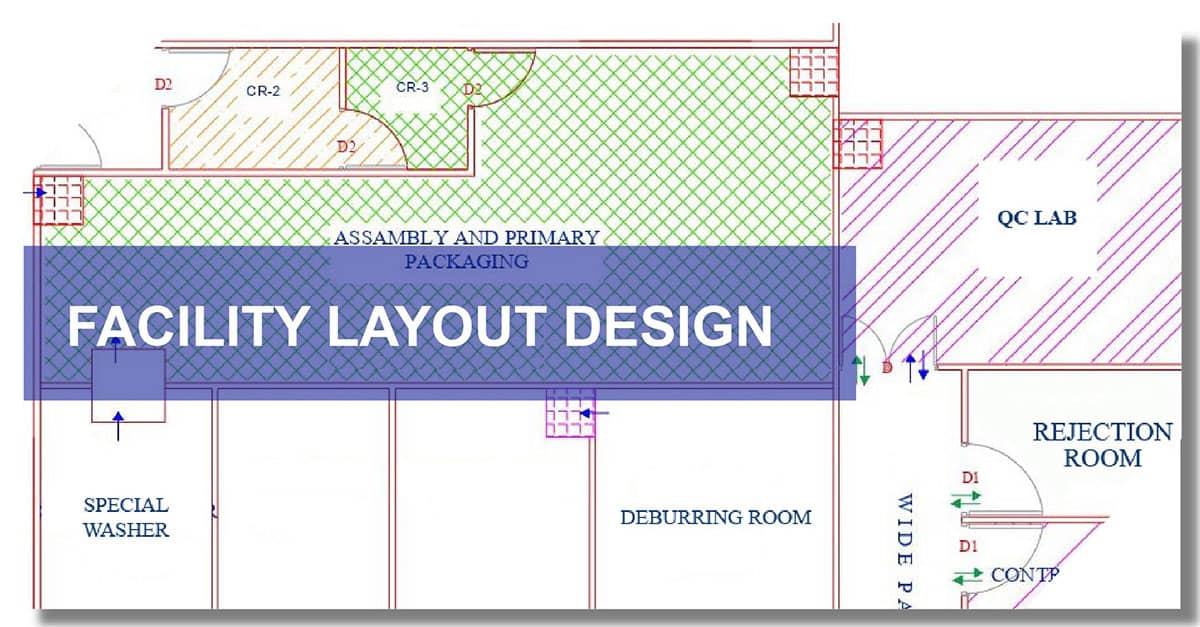

When it comes to the right design of the facility, the man and material flow are to be taken into consideration. The product segregation, product manufacturing flows and process steps, the use of the classified areas play an important role. Good experience handholding will lead to the correct decision making of the same this will ensure a smooth transition during audits from regulatory bodies & customers. The manufacturing plant layout design is prepared by our Auto-CAD expert based on inputs from the client & their architect/civil engineer.

The manufacturing plant layout design planning helps to determine the space requirements for various processes and their associated equipment/machinery. We incorporate design in such a way to ensure unidirectional flow of man and material and prevent cross-contamination. We also consult manufacturers on plans for future expansion or change & accordingly design the manufacturing plant layout. We incorporate efficient space utilization for maximum layout effectiveness in our designs.

How we help manufacturers in Manufacturing Plant Layout Design?

The best demonstration of compliance can be achieved by the right design. The right design minimizes the manual errors and requires the least effort in controlling the activities. Hence the right design of product, manufacturing site and the system plays a vital role in the quality of products and take care of the future issues that may crop up because of poor designs.

Operon Strategist study the requirements of the client, the product details & the manufacturing flow process to develop an adequate facility layout design which meets regulatory requirements as Oman, such as the unidirectional flow of man & material, prevention of cross-contamination, correct assignment of the clean room classification among other requirements. We also provide medical device regulatory consultation for India, Saudi Arabia, USA, Costa Rica, Egypt, South Africa & United Kingdom. For free consultation Contact us now.

There are various expectations “implied “and “expected to be understood” laid down by the regulators across the world. Some of the expectations can be well understood and compiled in the facility based on the experience of the regulatory audits. In the case of the existing facility, it is very important to know the facility compliance before applying for the regulatory audits to avoid the irreversible losses at the end of the facility audit.

As an experienced medical device regulatory consultants our manufacturing plant layout design is appreciated by various regulatory for their compliance and for minimal man and material movements and products segregation.