Traceability Requirements for Medical Devices in EU-MDR

Medical Device Regulations came into effect in May 2021 after replacing MDD in European Union, intending to make medical devices safer, more effective, and high quality. The main aim of EU-MDR is to ensure that the medical device manufactured or imported has increased safety, efficacy, and risk-benefit ratio and is easy to trace in case something goes wrong. EU-MDR works on all the possibilities that could go wrong when a medical device is launched in the market. That’s why the medical device directive (MDD) was replaced by the medical device regulations (MDR) 2017/745, as it is more elaborate and detailed, requires more evidence to prove safety, and had separately mentioned traceability requirements for medical devices. There were many incidents in the past of medical device failure or side effects that triggered the need to have a traceability system. Thus, MDR had to add chapter 3, called identification and traceability requirements for medical devices article 25.

Looking for Medical Device Consultants?

Let’s have a word about your project

After the implementation of MDR in the European Union, they prioritize closed-loop quality system traceability in medical devices. When a medical device manufacturer can achieve closed-loop quality system traceability, it proves that the device can mitigate and control the risk at any given stage, making it safer for the intended population.

How Eu-MDR Helps in the Traceability Requirements for Medical Devices?

- Medical device regulations trace the medical device throughout its lifecycle, which means traceability of the medical device is required at all stages from which a medical device passes which include manufacturing, development, and post-market activities. So, whether a manufacturer or importer, they must demonstrate that the device complies with closed-loop quality system traceability.

- It is because now EU-MDR has made it mandatory for the manufacturers and suppliers involved at any stage of a medical device to undergo a Quality Management System audit to prove their compliance with medical device traceability.

- The traceability from the design input to the device output can help to identify all the possibilities with the real-time visibility of the causes that can lead to the failure of the medical device. While designing the flaws is easy to locate and eliminate, real problems arise when challenges occur during the engineering process causing lot more changes.

- To help the manufacturers and suppliers with traceability MDR bought the concept of a Unique Identification Number (UDI), which helps to keep track of medical devices irrespective of the stage by assigning a device identifier and production series.

- The European Database of Medical Devices (EUDAMED) is a database system that carries all the information on medical devices being marketed in the European market. The main motive of EUDAMED is to make medical device information easily accessible to patients, regulators, notified bodies, and manufacturers. They can access the data of the medical devices being marketed. They can help the European Union to report adverse events noticed in the medical device, making post-market surveillance a little easy to maintain.

Types of Traceability That Can Be Established During the Medical Device Development:

- Traceability between requirements of product and tests.

- Traceability between the result of test measurements and national standards

- Traceability between devices, their material, and components from manufacturers to the intended user.

EU-MDR Requirements for Medical Devices :

- Lifecycle traceability of medical devices is required at all stages from development, design, manufacturing, and post-market surveillance so that manufacturers can easily trace materials and components.

- Must be able to see, understand and communicate the data with the organization’s quality management system.

- Must have a device identifier called UDI (unique device identifier), which must:

- Be placed on the package or label of the medical device.

- Use globally accepted formats.

- Have information on economic operators, as economic operators now include manufacturers, authorized representatives, importers, and distributors.

- Available at the manufacturer’s website and is available in print.

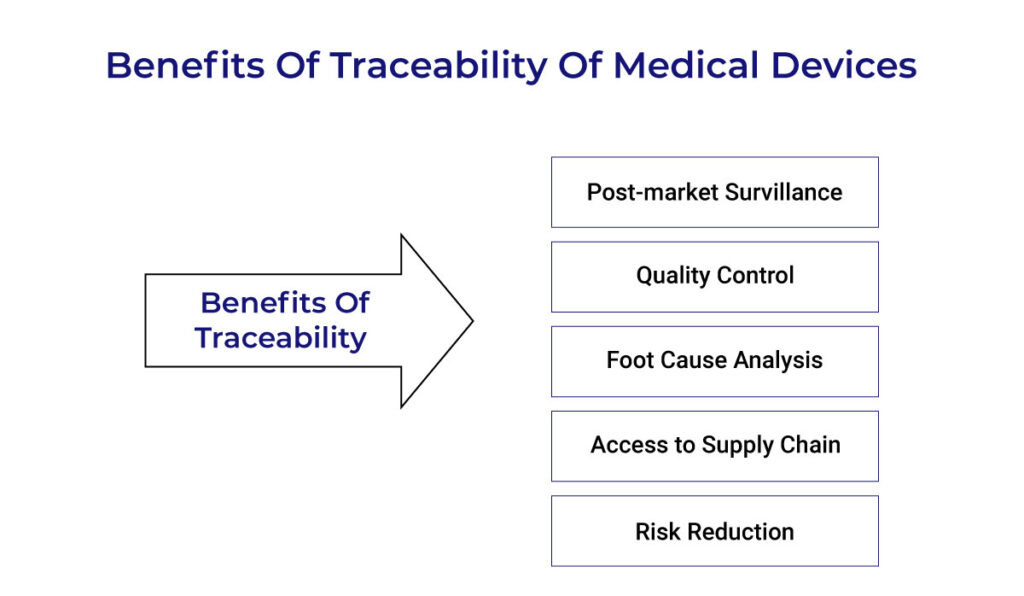

Benefits of Traceability of Medical Devices:

- Risk reduction – When a risk is reported in a medical device that can be traced easily, it can help alter the intended users. It can help the management recall defective devices, giving regulatory bodies, manufacturers, or suppliers an upper hand to react quickly. Traceability can help to identify the material used, components used, methodology used, and even batch number making it easy to mitigate and control the risks.

- Post-market surveillance – Even after the medical device is marketed and it shows some side effects, people can report it to a regulatory authority which can alert the manufacturer or supplier of the same concern. With the help of traceability, the manufacturer or distributor can find the medical device that may have caused the problem and update the post-market surveillance report.

- Quality Control –ISO 13485 and 14971 are the international standards of quality and help to set up the traceability framework. It allows manufacturers and distributors to comply with EU-MDR traceability requirements. Manufacturers can do traceability with the help of unique codes assigned to the medical device during design and production so that it won’t get lost among other devices.

- Supply chain – With the help of traceability, it identifies the defective device when applied at all stages, from designing to manufacturing to post-market surveillance. It can help the authorities trace the machine easily from the supply chain to the material used in the production line to the designing stage so that they can understand at what stage the problem arose.

- Root cause analysis – Traceability can help identify the root cause of the problem that occurred in a medical device and can help the manufacturer or distributors solve it quickly, save time, and establish their brand value.

After the technology for medical devices advanced, there were several reports of adverse events and side effects of medical devices from the intended population. Thus, regulatory bodies added specific chapters in MDR to maintain the medical device’s safety, quality, and efficacy and make sure it is traceable. Traceability is not the responsibility of the regulatory body alone but also of the manufacturer, distributor, or economic operator. As a medical device regulatory consultant, we help manufacturers or distributors to get compliant with the EUMDR regulations easily. After amending the traceability in EU-MDR, tracing a defective medical device in the European Union has become easy and quick.

Stay compliant and ensure the safety of your medical devices in the EU market with our expert guidance on EU-MDR traceability, along with our CE Mark medical device consultation services – Contact us today for a comprehensive consultation!