Medical Device development

Medical device development is the process of designing, creating, and bringing to market a device intended for medical purposes. It involves activities such as concept generation, design, prototyping, testing, regulatory approval, and manufacturing.

Medical device development seems to be a complex process with rigid requirements for FDA approval. Medical device professionals with significant expertise in the field of devices can comprehend and divulge rule pertaining to such goods to qualify in the market medical device development should address below 5 phases of development, while developing the devices QMS plays vital role, and as 21 CFR part 820 QSR consultant we are guiding them to implement effective QSM for their organization.

Looking for Medical Device Consultation?

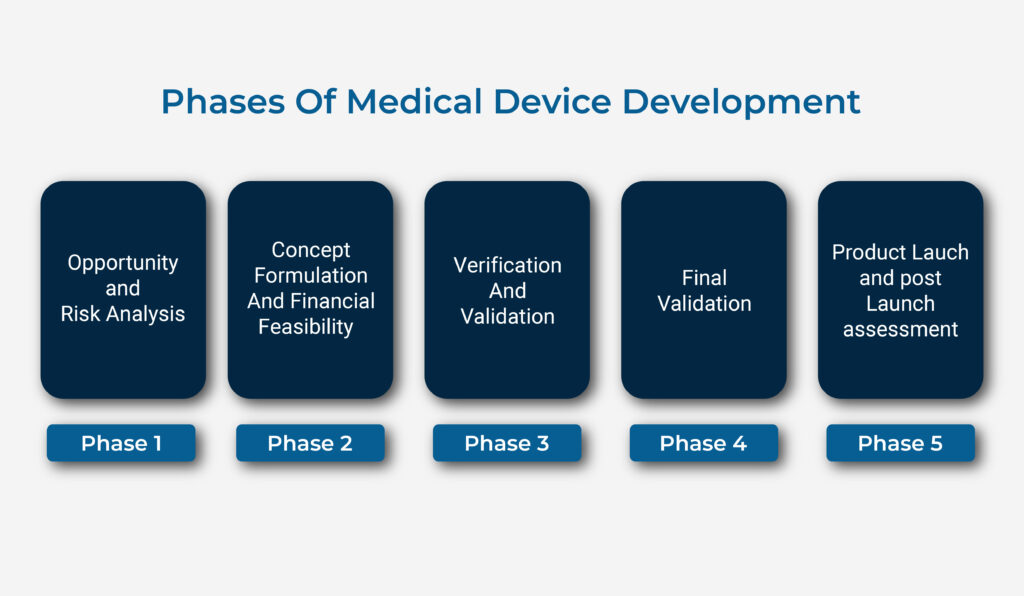

What are the Stages Phases in Medical device development?

The different legislative requirement and standards may impact the phases of medical device development. we are summarizing five phases of medical device design here :

- Phase I: Opportunity and Risk analysis:

for any medical device development risk analysis can be the first step to encash the opportunities. Risk analysis helps us to determine whether we proceed to next phase or not? this, phase works on design and development plan, risk benefit analysis, risk management plan etc.

- Phase II : Concept formulation and feasibility:

Once you are persuaded that your device has a market position, is practical and monetarily achievable, at exactly that point set the ball moving. You will require subsidizing for prototyping and trialing your device. This phase illustrates feasibility of your idea in various ways. Feasibility focuses on engineering design work, determining the key material and components, reviewing certifications etc. as far as product concept goes your plan should work on the incomplete work, the regulatory requirements, which will clear your path .

- Phase III : Verification And Validation

Now your device is beginning to take shape, you have a prototype, you have done some trials but you haven’t really put the design through its paces, you are about to go into validation and verification of your device and prove that it will really withstand all the pressures of the real world. You must perform a series of validation to ensure user need and intended use of the device are met

- Phase IV: Final Validation

Once you complete the above steps you are now came to a point where you are gathering all evidences of testing such as biocompatibility, electrical safety etc whichever applicable. After completing overall study, the technical documentation gets ready for submission. To create a technical file team of operon strategist can guide you and can submit your file to correct notified body . The NBs will review your technical file and also audit DHR, DMR and DHF. For any assistance in DHR, DMF you can freely contact us.

- Phase V: Product Lauch and post Launch assessment

Once the notified body certify your product and your QMS you can market your product.one need to verify their plan according to the regulatory requirement. Once you place your product on market you need to gather users feedback data regularly as part of risk management process .as per EUMDR these activities termed as PMCF and PMS ( Post market surveillance ).

This procedure of ideating, planning and building up a medical device is enormously perplexing, with many moving parts, documentation prerequisites and regulatory obstacles to survive. We have recorded just a couple of the procedures and necessities vital to the five phases, however they all show how focal great archive the board will be to your inevitable achievement. A well managed QMS will help you to easily meet the regulatory demands. These 5 phases of medical device development make the whole profitable for you and for the other stalk holders ..

FAQs

How do you design a medical device?

Medical device design is the first stage in the production of new tools, appliances, and instruments for use in a wide variety of medical and surgical processes. It includes not only the mechanisms and implements used to treat patients at hospitals and other medical facilities but also implantable, wearable, and portable medical devices that can perform the functions of human organs, deliver medication, and monitor patient vitals in real time. The functionality of the final product is dependent upon the design stage.

How long does it take to Develop a Medical Device?

Developing and gaining approval for a new medical device is not a fast process and can take many months or even years depending on the type of device being developed. Studies show that it takes three to seven years to bring a device from concept to approval. This may seem like a long time, but it includes the entire device lifecycle, including research, development and testing.

Does a Medical Device need FDA Approval?

All medical devices that are manufactured, repackaged, relabeled or imported for sale in the United States need some level of FDA approval. The FDA’s ‘Center for Devices and Radiological Health’ are responsible for regulating these products as well as medical and non-medical radiation-emitting electronic products such as lasers, x-ray systems, ultrasound equipment, microwave ovens and even colour televisions.

The required level of regulatory control increases with each class of medical device, from one to three. Most class one devices do not require Premarket Notification 510(k); most class two devices require Premarket Notification 510(k); and most class three devices require Premarket Approval.

What is Design Controls in Medical Devices?

Design controls is a formal methodology to drive medical product development activities, which are often mandatory. Medical device manufacturers must follow design control requirements under 21 CFR Part 820.30 to market all class 2 and 3 devices as well as certain class 1 devices such as software controlled devices.

Design control is a set of quality practices and procedures that control the design process to assure that the device meets the user needs, intended uses and specified requirements as well as improve and prevent future issues.

Operon Strategist is the leading medical device 21 CFR 820.30 design control consultant who has extensive experience and has done practical implementation of design controls regulation for developing new design control processes or for making improvements to existing processes.

What is Design Verification in Medical Device Development?

Design verification is a qualification testing methodology that ensures that a medical device is designed as it is intended. Verification is an internal process, which evaluates whether a design output meets the specified requirements, specification or regulation defined in the design input. Verification testing may occur at any point in the process, beginning from the ideation & conceptualization phase to the post-production phase.

What is Design Validation in Medical Device Development?

Design validation is a testing from the market perspective. It is intended to validate whether a medical device is meeting the user’s needs. Successful validation proves that a device meets needs of users in the targeted market. Although validation comes into the picture at a later stage of product development process, it still measures the very first part of the complete process, which is defining user needs. Validation must involve testing and clinical evaluation. Also, it requires a device to be developed in the production environment with an involvement of end-user for actual or simulated testing.

Why is Design Verification and Validation needed?

Medical device users look for effectiveness and safety of devices that they use to address a particular problem or condition, which are sometimes critical to life. This is why iterative testing with verification and validation of these medical devices becomes imperative. Verification and validation of medical devices in the design process aim to ensure that the device is aligned with the need of targeted users and delivers the intended solution. It also helps ensure whether all the requirements are being satisfied. It helps to comply with regulations as well as designing the highest quality product.