Blood Collection Tube Manufacturing

A Blood Collection Tube Manufacturing is of BCT/ Vacutainer which is a sterilized glass or plastic test tube with a coloured rubber stopper which creates a vacuum seal inside the tube supporting the draw of a fixed volume of liquid. It is also referred to as the “Vacutainer”. Vacutainer tubes consist of additives which are designed to preserve the specimen earlier to the accurate testing.

These tubes or containers have a security planned plug with en number of labelling alternatives and draw volumes. The shading on the top shows the added substances of the containers or tubes. Vacutainer tubes may contain extra substance that preserves blood from preparing in a medical research laboratory. Utilizing an inappropriate tube can make the blood test unusable for the intended purpose.

Looking for Consultant?

Let’s have a word about your project

Furthermore, some tubes contain added substances that save certain segments of or substances inside the blood, for example, glucose. At the point when a tube is centrifuged the materials inside are isolated by thickness, with the platelets sinking to the base and the plasma or serum gathering at the top. Tubes containing gel can be effectively taken care of and moved after centrifugation without the platelets and serum blending.

Blood collection tubes are notified devices now; Earlier they were non-notified medical devices and according to the new notification from CDSCO, notified medical devices will come under licensing regime soon. So for the manufacturer, CDSCO registration will be mandatory for their medical devices. Our team will guide you to complete the CDSCO registration process easily.

Blood Collection Tube Types

- No Additive Tube – This tube is used for collecting blood and storing it for biochemistry, serology and other tests. It provides non-contaminated serum samples for clinical tests, keeping the serum stable for an extended period of time.

- Serum blood collection tube – This tube aims at giving high-quality serum sample for medical technologies. It has 3 kinds of tubes: no additive tube with & without clot activator and brick red cap.

- Hemo Repellent Coated tube – blood collection and storage for biochemistry tests, silicon are used. It is appropriate for a broad range of operations, and quick in coagulation. These blood cells do not stick to the side of the tube.

- Gel + BCA – such tubes are used for clinical and biochemical immunology. There’s a barrier gel present inside the tube at the bottom. After the centrifugation, the gel can easily separate the serum from the cells without causing additives to exchange between blood cells and serum.

- Whole blood collection tube – this tube provides good quality of blood sample for the laboratories. It has 2 kinds of tubes (ETDA) (ETDA.K2/K3 and ESR tube.

- ETDA tube is used for haematology and also as various kinds of blood cell test instruments.

- ESR tube is used for blood collecting and anticoagulation rate test.

- Plasma blood collection tube – plasma blood collection tube gives a high quality plasma sample for medical laboratories. This includes 3 kinds of tubes:

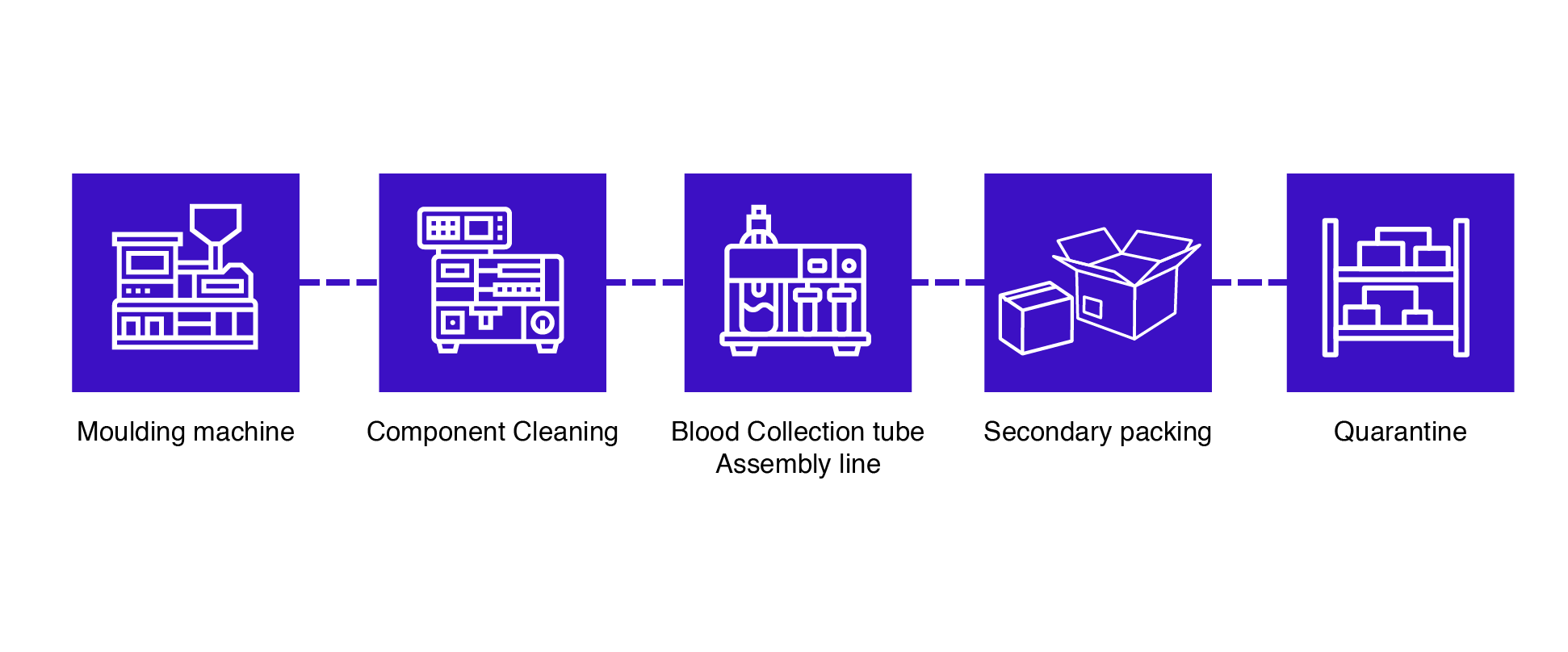

Blood Collection Tube Manufacturing Process

Molding Machine

Molding Machine

The molding machines are used for making small plastic tubes that are made to collect blood samples in it. The molding machines can be of many different types, like an electric molding machine.

Component Cleaning

Component cleaning or parts cleaning is significant to all industrial processes as preparation for surface finishing or else to protect the essential components. Electroplating is generally a sensitive part of cleanliness since the molecular layers of the oil can keep the adhesion of the coating.

Blood Collection Tube Assembly Line

An assembly line has to assemble cleared blood collection tubes with various tube sizes. The limit of the basic line layout is 200 parts/minute and it carries all processes from feeding and sorting of the tubes to the caps/closures and dosing of all kinds of testing agents. There are two types of BCT assembly lines,

- Automatic (fully)

- Semi-Automatic

Secondary Packing (Gamma Sterilization)

Sterilization is a process that efficiently kills or deletes all the micro-organisms like bacteria, and other viruses. There are various types of sterilization process that depends on the type of material and its sterilization process.

Quarantine (Finished Goods Store)

The quarantine period or process helps to assure that there is no defective or infectious product that is reaching the consumers.

Need More Clarity on the Process of Blood Collection Tube Manufacturing

Blood Collection Tube Manufacturing Machinery

- BCT Cap and stopper Combination Machine

The blood Collection Tube cap machine is used for inserting the rubber stopper cap into the plastic cap for the blood collection tube cap. It has 24 pcs of assembling punches with two sets of vibration material loaders, which exactly fit the rubber stoppers and caps running in one row.

- BCT Labeling machine

In the packaging industries, sticker labeling machine is used for applying labels and stickers on products, containers, tubes, injections, bottles, etc. As labeling plays a significant role, these machines have a huge demand in industries. There is a number of labeling machines available in the market according to their types and features.

- Dosing machine

The dosing machine is an automated system for feeding the equipment with products that contain liquid like lubricants and water.

- Capping machine

Capping machines are used for applying plastic and metal threaded caps as well as plastic snap caps, fitments, corks, and plugs.

- Centrifuge machine

A centrifuge is equipment that pushes the object in a rotating motion around the fixed axis by applying a force that is very strong. The centrifuge works with the help of the sedimentation principle, where the centrifuge’s acceleration can cause denser substances and particles to move outwards in a radial position.

- Shrink packaging machine

Shrink tunnels using a heated air system, it used for shrinkable films (PE POF PVC) that have been applied by L-bar sealers, sleeve wrappers, and sealing cutters. Planned for high production, the airflow method helps to circulate the air to avoid bubbles and bumps in plastic film.

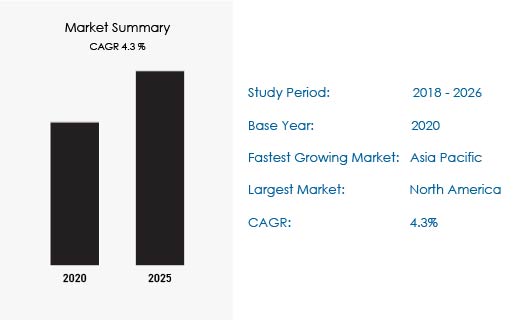

Market Growth for Blood Collection Tube Product

The interest in blood collection could be hampered by dangers related to blood transfusion, for the most part in underdeveloped countries. In any case, there are a few awareness plans and crusades led by governments and outside people to handle this issue. The command of enlisting capable and qualified healthcare services experts could make great development prospects on the planet’s blood collection market. Besides, technological advancements in blood collection methods and items have opened a few entryways of chance for the key players in the blood collection market throughout the years to come.

Ready to Bring Your Blood Collection Tube Manufacturing Vision to Life?

Streamline Blood Collection Tube Manufacturing with Operon Strategist

Looking to set up a blood collection tube manufacturing unit? Operon Strategist’s team of experienced manufacturing consultants is here to help. We specialize in blood collection tube manufacturing plant layout design and unit setup, as well as obtaining the necessary regulatory licenses for blood collection tube manufacturing. Contact us today to get started on your project and ensure a seamless manufacturing process for high-quality blood collection tubes.

Operon strategist medical device regulatory consultancy provides the best regulatory service to tap the growing market. Feel free to contact us for your queries, our team will happily assist you.

Visit Our Manufacturing Blogs for More Information.

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

Molding Machine

Molding Machine