The Impact of Change on Medical Device

Medical technology and medical device companies have great impact on health care sector. To pursue change to any technology is to keep evolving the needs of the world. Unlike others, medical device company has to make changes to their device constantly.

The advancement in technology or process allows to provide patient’s better care and condition of life. The change to the medical device is always expected to be good and follow the mandatory regulatory norms, where the ultimate purpose of safety, improved quality and cost effectiveness should be served.

The changes to medical device can be driven by various factors like:

- To update specific process or product

- To increase the quality and safety of the product

- To make the post- market changes due to user/regulatory complaints

- To ease the usage of product

- To upgrade the technology and many more…

When we talk about the change to the medical device here, we say about device change or the changes made to the medical device. These changes are classified based on the criticality. A change refers to the SIGNIFICANT when it involves the design change or the change in the intended purpose of the medical device.

Examples

Change in shape of knife to improve its performance during surgery. Change in intended purpose of the software as if it is designed just for detection of problem, changing this to fixing of problem. The changes can be classified as major, minor or critical depending on its impact on the system. Major change is when there is change in design, raw material or the technology according to need. For e.g., change within the raw material or redesigning the device, or changing the technology.

- Medical devices design and development is the urgent stage for its prosperity Operon strategist is there to guide you with the design consulting for medical devices.

Looking Forward For Medical Device Design and Development?

As a Medical device development and Development consultant, we provide expertise Medical device development solutions to medical device manufacturers.

Minor change is when it does not affect the product e.g administrative change in the work area. Critical change is when it needs extensive planning, documentation changes and needs significant capital.Design change affects the form, fit and function (FFF). The form-fit-function is related to design of the device and is discussed as the “physical, functional, and performance criteria or characteristics of the entire assembly or the components which gives unique identity to a device and has impact on change.”

during the design change technique, the manufacturer has to closely monitor whether the new change or the trade in part meets the form-match -characteristic of the medical device.To make any changes to any design or process the manufacturer should consider FFF requirements. Form defines the look of the device. It is the physical properties of device i.e. the shape, size, dimensions, color or visual parameters that are characteristic to the item. E.g. here we can describe a spacer or the plastic tube of the inhaler which has one mouthpiece at the end

Fit is the ability of an item to interconnect with other components or to become the integral part of another assembly. E.g. we want our spacer or the plastic tube to be correctly fit to the final product Function refers to the action or the function that the item is going to perform and because of which there is the existence of the device. E.g., Spacer extends the amount of time for the medicine to enter the lungs and it is very helpful for the children.

If we make any changes to improve the performance of the device, the change assessment team need to assess the proposed change and it has impact on FFF. When the change is made to the medical device and is significant then change and design control management comes into picture.

Change and Design Control Management

The need of change and control management is to meet the regulatory requirements of FDA and other governing bodies. It is the effective way to create safe product and satisfy the patient/user needs. It is the best practice in developing the best product. Change and design control management helps us to learn to be successful in developing products that meets the customers need.

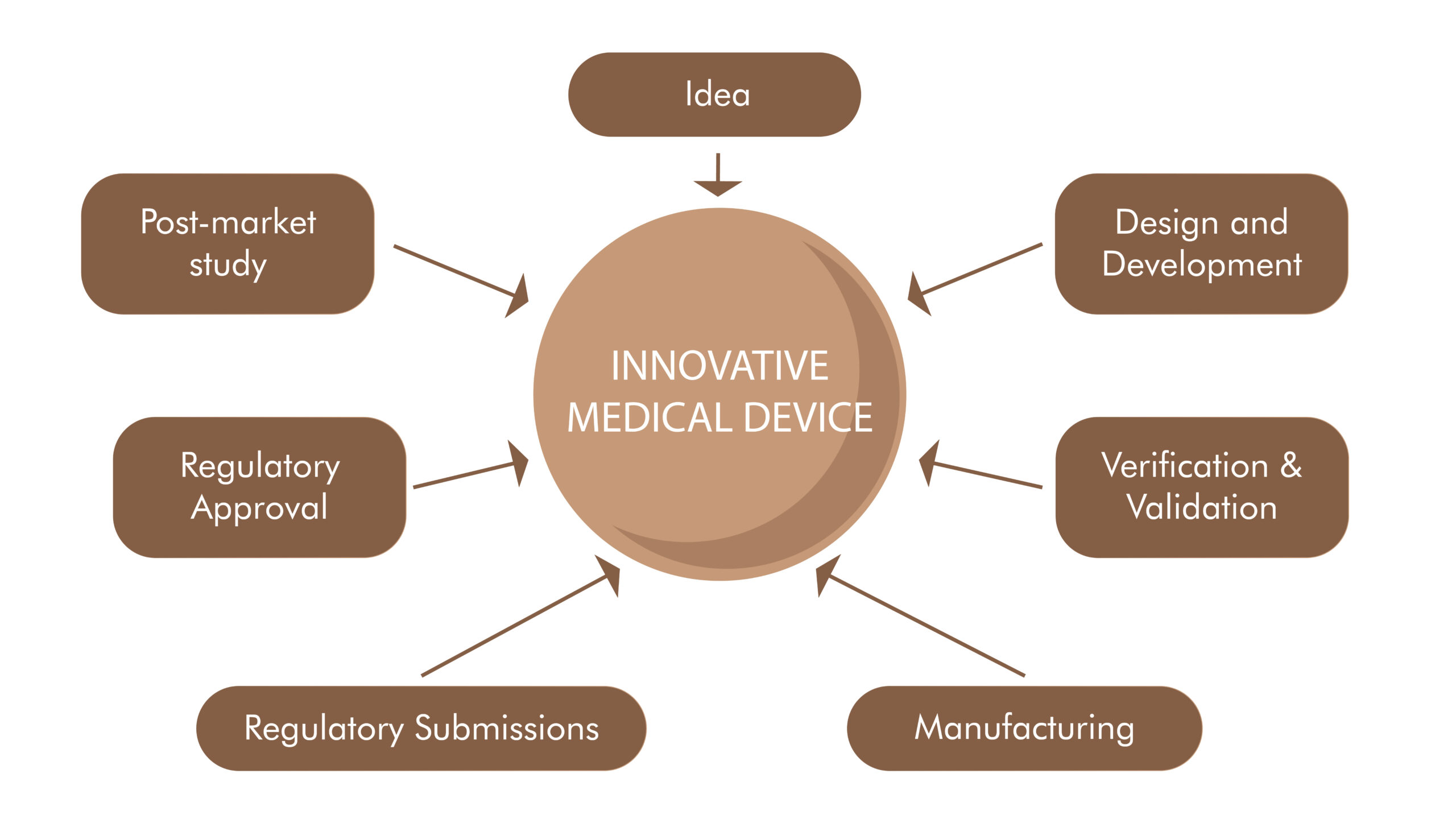

Innovative Medical Device

The above cycle well describes the steps to develop and deliver your innovation (innovative medical device). FDA and other regulatory bodies maintain the systemic approach to control changes to products.

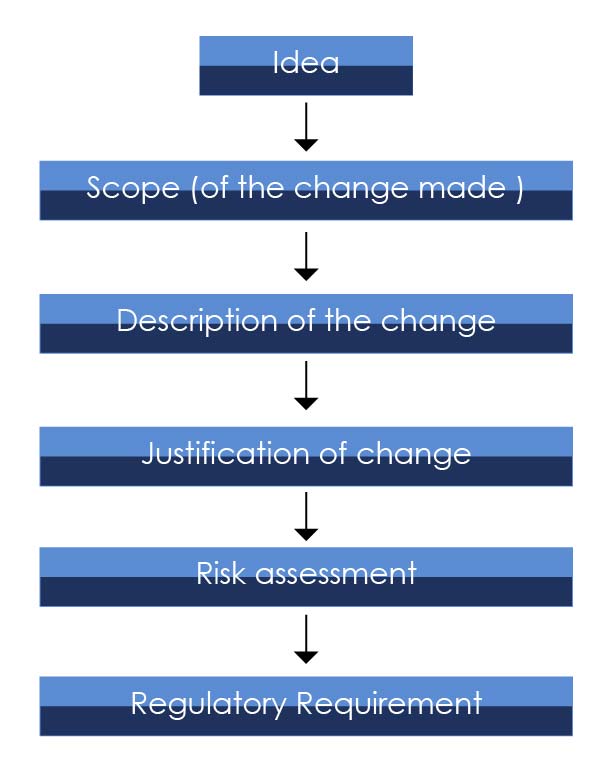

Steps involved in Change Management

- Identify the need of change e.g. One of the case studies gives the example of change in catheter logo from one side to another.

- Justification to the change made e.g. Though the change in position of catheter logo made marketing department unhappy, was insignificant but analysis suggested that it could impact the device\’s safety and efficacy.

- To review the change. Here, it means the technical reviewing the proposed change.

- To Approve the change

- To document all the steps. It is the most important step to change made to medical device

- Communicate the change to the respective personnel

- To implement the change

- To evaluate the change

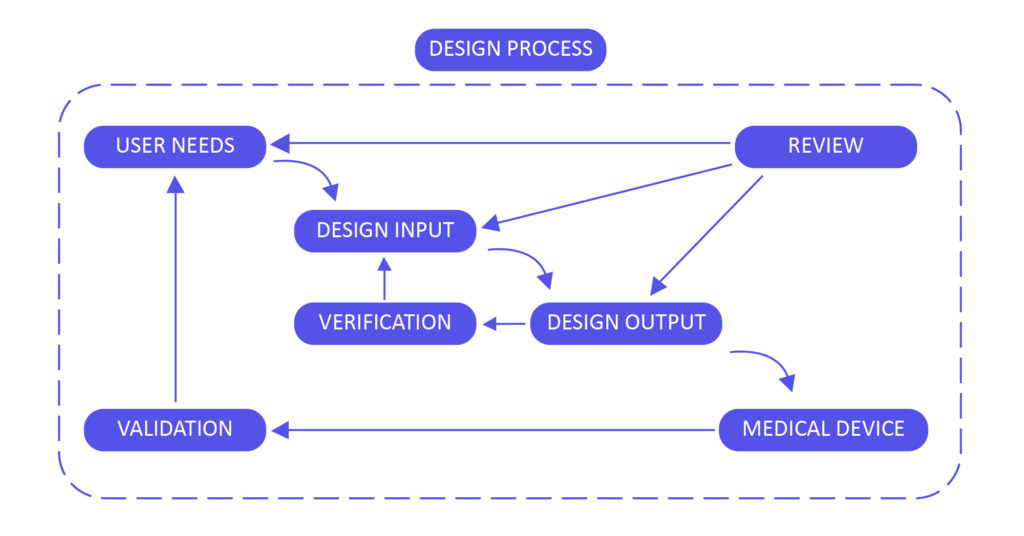

The figure describes the art of design change inputs and validation for the same.

Impact of Change on Medical Device

Here we talk about the major changes made to the medical device to how it works or is used. Making changes to medical devices is essential part of the design change to improve your product and make a product a huge success.

The change to medical device has huge impact on cost development. Biological safety assessment is the parameter considered while making changes to the medical device. The change has its effect within and outside the machine. here the exchange has its role extended to impact assessment group which involves technical group i.e R&D, QA, regulatory affairs, validation, marketing, engineering, quality controls, risk management and environment safety.

Change Impact Assessment

The impact of change should be assessed to all possible areas with records and justification. E.g., Any change made to medical device and which is significant is definately goining to have the impact on biocompatibility, safety, efficacy and performance of the device. The change impact assessment process provides a record of impact decision and action taken.

Here, the Risk -based approach is to be considered which means analysing the risk associated factors and beneficial factors. The risk associated factors should be identified and its severity and frequency should be assigned to determine the risk level and verified for its acceptance. Change should focus on benefit assessment for product availability and the compliance associated should be minimum. Risk assessment and management is required to improve the intended purpose of the change. Testing the consequences of changes like material change, change in supplier or material similarities has important impacts on the change made to medical devices. The updates of the risk documentation are required.

Change assessment chart involves the following steps :

Regulatory Requirements

The need for change control is outlined in US FDA QSR (Quality System Regulation) (21 CFR part 820) and in ISO 13485:2016. The manufacturers need to have comprehensive, descriptive documentation.

- US FDA 21 CFR Part 820.30 (i) outlines the design change where it describes

Each manufacturer shall establish and maintain procedures for identification, documentation, validation or where appropriate verification, review, and approval of design changes before implementation.

- FDA 21CFR part 820.40 (b) outlines the document changes where it describes

Changes to documents shall be reviewed and approved by an individual(s) in the same function or organization that performed the original review and approval, unless specifically designated otherwise. Approved changes shall be communicated to the appropriate personnel in a timely manner. Each manufacturer shall maintain records of changes to documents. change records shall include a description of the alternate, identification of the affected documents, the signature of the approving individual(s), the approval date, and whilst the exchange turns into effective.

- FDA CFR part 820.70(G) outlines the production and process change

(b) Production and process changes. Each manufacturer shall establish and maintain procedures for changes to a specification, method, process, or procedure. Such changes shall be verified or where appropriate validated according to § 820.75, before implementation and these activities shall be documented. Changes shall be approved in accordance with § 820.40.

ISO 13485:2026 Design and development changes

Many countries rely on ISO standards for quality control standards and ISO 13485:2016 sets out a series for design control requirements. ISO 13458:2016, Medical devices — Quality management systems — Requirements for regulatory purposes, section 7.3.9 (Control of design and development changes) states:

The organization shall document procedures to control design and development changes. The organization shall determine the significance of the change to function, performance, usability, safety and applicable regulatory requirements for the medical device and its intended use. Design and development changes shall be identified. Before implementation, the changes shall be:

- reviewed

- verified

- validated, as appropriate

- approved

The review of design and development changes shall include evaluation of the effect of the changes on constituent parts and product in process or already delivered, inputs or outputs of risk management and product realization processes. Records of changes, their review and any necessary actions shall be maintained.

EU MDR

EU Medical Devices Regulation (MDR) provides new regulatory obligations for certain medical devices where, such devices must comply the MDR if a ‘significant change’ is made to their design or intended purpose and therefore it should undergo relevant MDR conformity assessment before placing to EU market.

MDGC guidance

This provides the manufacturers the guidance of whether the change made to their device is significant change or the change affects indications, contraindications or clinical performance of the device.

According to MDR guidance the changes are classified into five categories

- Intended purpose

- Design or performance specifications

- Ingredient or material

- Sterilisation or packaging design with impact on sterilisation

- Software

The notified bodies should assess any change made to medical device and its impact.

Conclusion

Change to medical device is a perfect privilege because we make difference in people\’s life as it reduces pain, improves quality of life and responsibility as indeed. The emerging technologies safety is a challenge and need on quality management is necessary and meeting the FDA and other regulatory requirements is necessary to ensure safety to the product.