Introduction to Stent Manufacturing:

In the vast landscape of healthcare, stents stand as unsung heroes, silently working their magic in the realm of cardiovascular and vascular treatments. These unassuming devices have not only saved countless lives but have also redefined medical possibilities. In this comprehensive guide, we will embark on a fascinating journey into the world of stent manufacturing. We will peel back the layers, uncover the intricate process, explore the materials that make it all possible, and shine a light on the profound significance of these small yet life-changing marvels.

Want to take your stent manufacturing project to the next level? Contact Operon Strategist today for expert guidance on manufacturing plant layout design and turnkey solutions that can transform your stent manufacturing project.

Looking for Medical Device Consultant?

Let’s have word about your project

Understanding Stents: Tiny Tubes with a Tremendous Impact

Before we plunge into the heart of stent manufacturing, let‘s first acquaint ourselves with these medical marvels and understand why they are indispensable in modern healthcare. Stents are small, tube-like structures inserted into arteries and blood vessels, ensuring the uninterrupted flow of life-giving blood. Their mission: to alleviate distressing symptoms, reestablish vital blood flow, and thwart life-threatening conditions such as heart attacks and strokes.

Types of Stents: Tailored Solutions for Varied Needs

Stents come in several different types, each designed to address specific medical challenges. Let’s explore the most common ones:

- Coronary Stents: Silent protectors of the heart’s vital arteries, combating coronary artery disease (CAD).

- Peripheral Arterial Stents: Guardians of peripheral blood vessels, battling peripheral artery disease (PAD).

- Esophageal Stents: Offering relief in the esophagus, clearing the path for those battling obstructions caused by tumors or strictures.

- Biliary Stents: Navigating the bile ducts, these stents alleviate obstructions and enhance bile flow.

- Ureteral Stents: Masters of urinary tract management, easing obstructions within the ureters.

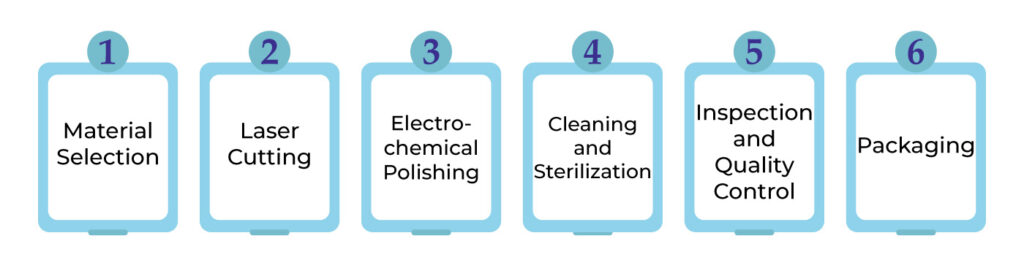

Step-by-Step Stent Manufacturing Process:

Stent manufacturing is a complex blend of precision engineering and cutting-edge materials. Here’s a glimpse into the intricate process:

- Material Selection: Stents are typically crafted from medical-grade materials (Metals & Polymers), metals such as stainless steel, cobalt-chromium, or nickel-titanium alloys and polymers such as nylon, polyurethane are utilized. The choice depends on the stent’s intended purpose.

- Laser Cutting: Laser precision carves intricate patterns in the stent structure. These patterns serve as the blueprint for expansion when the stent is in place, ensuring sturdy support for the vessel.

- Electrochemical Polishing: To ensure smooth and biocompatible surfaces, stents undergo meticulous polishing, erasing any imperfections or rough edges.

- Cleaning and Sterilization: Stents undergo rigorous cleaning and sterilization processes to eliminate contaminants, preparing them for their noble medical mission.

- Inspection and Quality Control: Every stent is subjected to rigorous quality checks, ensuring it meets the industry’s strict standards.

- Packaging: Stents are carefully cocooned in packaging that safeguards their sterility and integrity until they are deployed by healthcare heroes.

Ready to Bring Your Stent Manufacturing Vision to Life?

The Significance of Stent Manufacturing: Elevating Healthcare Standards

The impact of stent manufacturing cannot be overstated. Stents are not just lifesavers; they are the bridge between patients and health. They prevent and treat severe medical conditions like heart disease and stroke, offering minimally invasive alternatives to traditional surgeries. Beyond this, advancements in stent manufacturing have ushered in a new era with drug-eluting stents, delivering medications to further enhance patient outcomes.

Elevate your Stent manufacturing to new heights with Operon Strategist, your go-to partner for expert manufacturing plant layout design for medical devices and turnkey project solutions. Contact us today to transform your stent manufacturing.

Visit Our Manufacturing Blogs for More Information.

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/

-

Operon Strategisthttps://operonstrategist.com/author/snehal/