Why Hand Sanitizer Manufacturing is a Growing Opportunity

The demand for hand sanitizers surged during the COVID-19 pandemic and remains high due to global hygiene awareness. For manufacturers and startups, hand sanitizer production is a scalable and profitable business while contributing to public health. However, high-quality manufacturing requires strict adherence to formulation guidelines, regulatory requirements, and precise processes.

For global compliance, manufacturers must follow WHO and FDA guidelines and ensure their products are safe and effective.

Looking for Medical Device Consultant?

Let’s have word about your next project

Types of Hand Sanitizers

Alcohol-Based Hand Sanitizers

- Contain 60–95% alcohol (Ethanol or Isopropyl Alcohol).

- Recommended by WHO and CDC for maximum effectiveness.

- Regulated as a drug in many countries.

Non-Alcohol-Based Hand Sanitizers

- Use antiseptics like benzalkonium chloride.

- Less effective against some pathogens.

- Often classified as cosmetic products.

7-Step Hand Sanitizer Manufacturing Process

Step 1: Formulation

Prepare high-quality sanitizer with precision:

- Ethanol-based: Glycerin 1.45%, Ethanol 80%, Hydrogen peroxide 0.125%, QS water.

- Isopropanol-based: Glycerin 1.45%, Isopropanol 75%, Hydrogen peroxide 0.125%, QS water.

All formulations must comply with FDA standards for alcohol concentration and pH balance. Avoid adding unauthorized fragrances or extra ingredients. Choosing the right formulation ensures the sanitizer is effective against viruses and bacteria while remaining gentle on the skin.

Step 2: Mixing of Ingredients

- Mix water and Carbopol to form a smooth gel.

- Gradually add alcohol to achieve 70–80% final concentration.

- Optionally, add humectants and preservatives.

- Use high-shear mixers to prevent clumping or aeration.

During mixing, maintaining proper temperature and avoiding rapid alcohol addition is crucial to prevent evaporation and ensure uniform consistency. This step ensures a smooth gel texture and long shelf life.

Step 3: Sterilization

- Ensure all materials and water are sterilized.

- Handle flammable alcohol with proper safety equipment.

Step 4: Filling

- Use automatic filling machines for accuracy.

- Handle various bottle shapes and viscosities.

Step 5: Capping

Automatic capping machines with torque control ensure tight seals.

Step 6: Labeling

- Use round wrap, double side, or combined labeling machines.

- Include product info, safety instructions, and branding.

Step 7: Testing and Quality Assurance

- Check alcohol content using alcoholmeter or hydrometer.

- Follow FDA and WHO guidelines for product safety.

- Conduct periodic quality checks to ensure consistent gel viscosity, clarity, and effectiveness.

Key Machines Used in Hand Sanitizer Manufacturing

- Sanitizer Filling Machine: Semi-automatic or fully automatic.

- Digital Filler: For volumes from 10 ml to 1000 liters.

- Sealing Machine: Handles various container shapes.

- Capping Machine: Single or multi-head with torque adjustments.

- Labeling Machine: Supports round, double, and combined labeling.

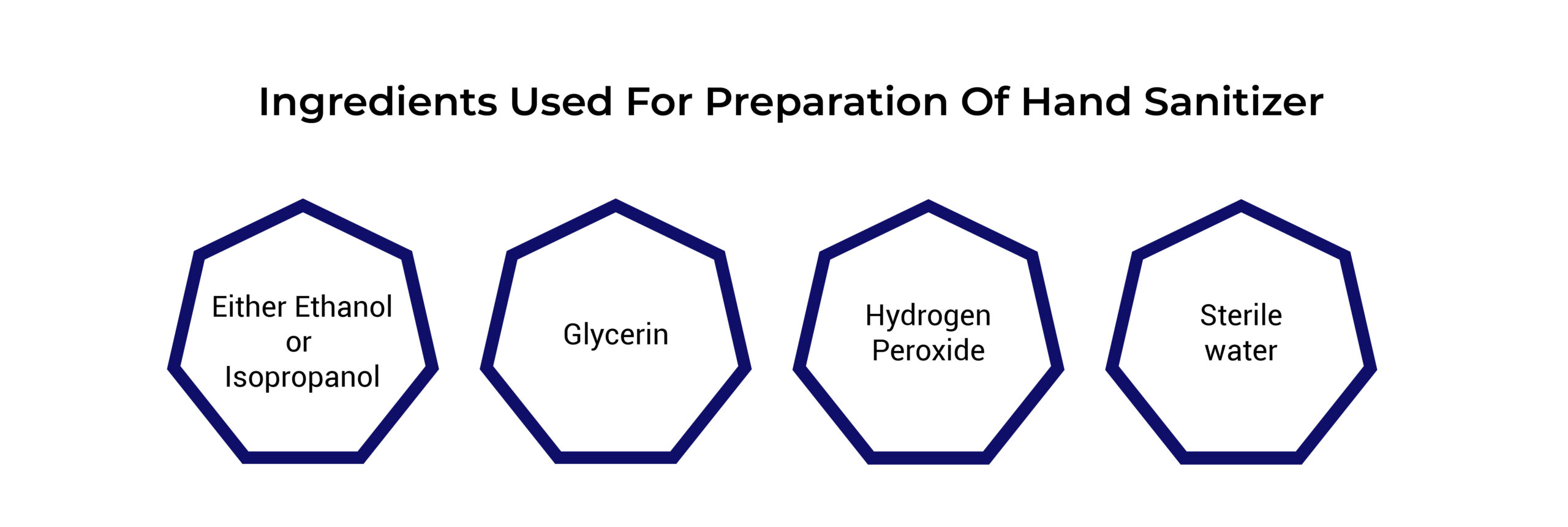

Ingredients Required

- Ethanol or Isopropanol (main disinfectant)

- Glycerin (skin-friendly humectant)

- Hydrogen Peroxide (to inactivate bacterial spores)

- Sterile Water (QS)

Sourcing Materials and Safety Notes

- Sterile Water: Boil and cool before use; avoid adding alcohol near heat.

- Ethanol: Must be denatured to prevent ingestion.

- Use proper PPE, ventilation, and explosion-proof equipment.

Testing and Quality Control

- Verify alcohol concentration and consistency.

- Ensure proper pH, viscosity, and absence of microbial contamination.

- Follow FDA, WHO, and local regulatory testing requirements.

Ready to Start Your Hand Sanitizer Manufacturing Journey?

Why Choose Operon Strategist for Hand Sanitizer Manufacturing

Operon Strategist helps manufacturers, startups, and global businesses navigate Hand Sanitizer Manufacturing with full compliance. Services include:

- Medical device registration (FDA, CDSCO, CE, UKCA)

- ISO 13485 certification & QMS implementation

- Plant setup, turnkey solutions, and technology transfer

- Regulatory compliance, audit readiness, and documentation

- Material sourcing, supply chain optimization, and testing

- We guide you to manufacture high-quality, compliant products and scale your business globally.

Contact us today to start your Hand Sanitizer Manufacturing journey.